Whether it’s the rapidly growing demand for electricity, the energy transition or digitalization—the complexity of the requirements placed on transformer manufacturers is increasing. Nantong Hyosung Co. Ltd. from China has therefore entered into a strategic partnership with MR and can now offer lean system solutions to a global clientele.

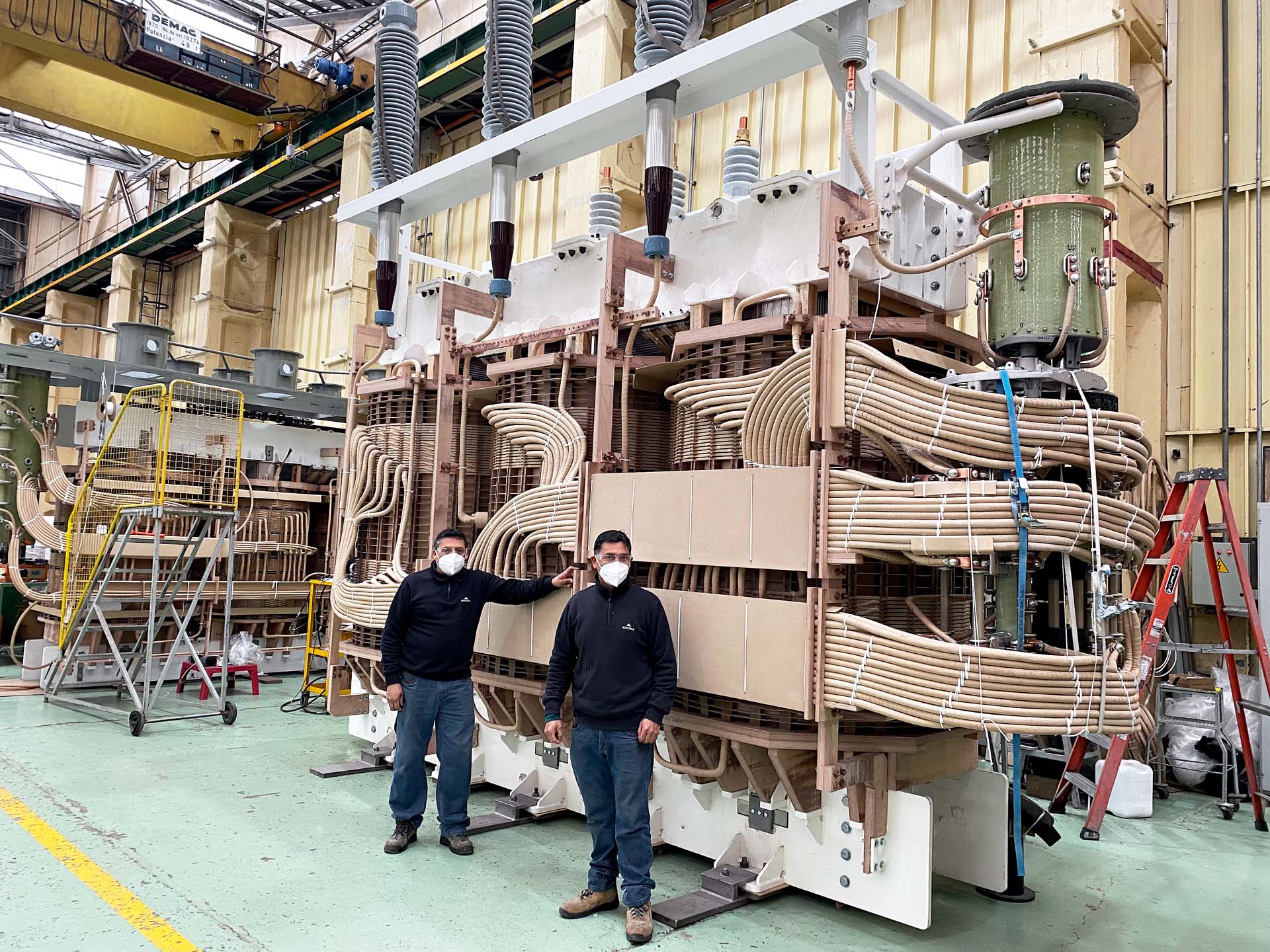

Transformers from Nantong Hyosung Co. Ltd. are already humming in over 70 countries, ensuring a reliable power supply. The transformer manufacturer, which belongs to the Korean conglomerate Hyosung, produces in the megacity of Nantong in China for power generators as well as public and industrial network operators worldwide. Three-quarters of its production goes abroad.

Nantong Hyosung faces similar challenges like many other transformer manufacturers: Grid development is very dynamic around the globe. Everywhere, the demand for electricity will rise sharply in the coming years—due to the growing population, but also because of new loads brought about by the electrification of the mobility and heating sectors. Added to this are the fluctuations caused by the integration of renewable energies. In order to be able to control these developments, digital solutions and thus intelligent resources are increasingly in demand. And anyone who supplies the whole world, like Nantong Hyosung, must also comply with numerous different national regulations. In short, the transformer business is becoming more complex. And also more demanding. On the other hand, customers are demanding lower costs, short delivery times, and professional service.

Strategic partnership with MR

So how can this complexity be managed? Jae Seong Jang, General Manager of Nantong Xiaoxing Transformer Co. says, “Robust technologies, customized designs and excellent project execution are part of our business philosophy. In order for us to deliver on this promise in the future, we need cost-effective complete solutions.” So the Chinese transformer manufacturer entered into a strategic partnership with MR. “MR is the world market leader and offers a comprehensive range of transformer-related solutions that are already specified for global use and meet international standards,” says Jang.

In addition to on-load tap-changers, sensors and protection devices, it is primarily the ETOS® system solution for digitizing power transformers that helps Nantong Hyosung serve its demanding customer requirements. Since it works on the plug-and-play principle, it not only reduces production costs. It also eliminates the need for many cables and on-site assembly work. Since all components come from a single source, ordering processes are also more efficient. And the partnership offers yet another advantage: Since MR has a worldwide service network, operators who use transformers from the Chinese manufacturer also benefit. Jang is convinced: “All in all, the cooperation is a classic win-win situation for all parties involved.”

Your Contact

Do you have any questions about the project?

Zhenyu Wu is there for you:

Z.Wu@cn.reinhausen.com