How well do you know your transformer? Intelligent MSENSE® sensors in combination with ETOS® , the first open operating system for power transformers, continuously provide you with all relevant information as well as recommendations for action in regard to all questions crucial to reliable operation.

What damages the transformer

The service life of a transformer is crucially dependent on the transformer’s operating conditions and its environment. Loads are significantly higher in an industrial application than they are in normal grid operation. One way or another, it is important to be aware of the weak spots of the transformer in order to prevent damage and disruptions at an early stage.

3 % points in the moisture in the insulation make a big difference. When the moisture level in the insulation increases from 1 % to 4 %, the service life expectation drops from around 35 years to fewer than 5 years.

17 % of transformer failures can be traced back to defective bushings.

45 % of all transformer failures are the result of problems with the windings.

INVISIBLE and undetectable from the outside: this is the nature of mechanical irregularities, time differences in switching operations and anomalies in the tap changer.

12 °C An increase of just 12° C in the winding temperature reduces the service life of the transformer by 75 %.

30 ppm This corresponds to a share of 0.000003 % and is a critical value of moisture in the oil.

26 % of transformer failures can be traced back to anomalies in the on-load tap-changer.

Sensors with System

Reinhausen offers the MSENSE® sensor family and the maintenance-free MTRAB® dehydrating breather in combination with ETOS® as a perfectly customized software and hardware system.

Learn more at: msense.reinhausen.com

What should be done with the treasure trove of data?

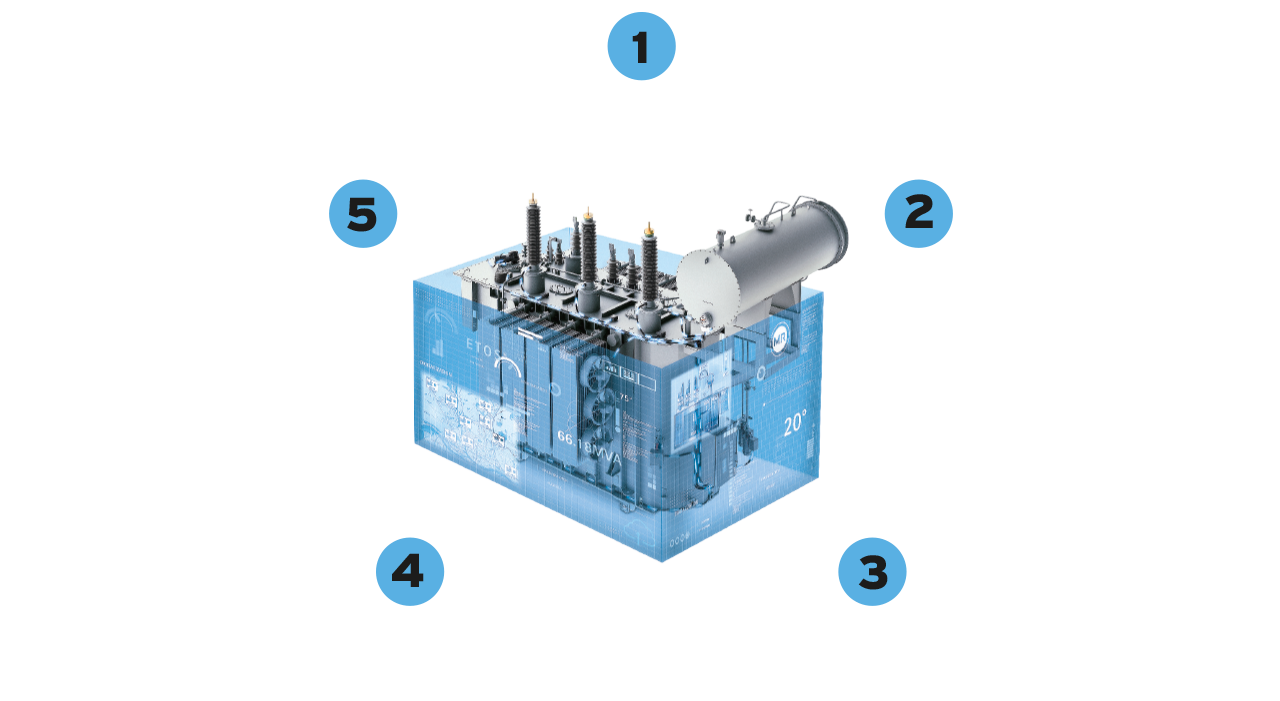

The MSENSE® realizes its full potential when combined with ETOS®, the first open operating system for power transformers. This intelligent system helps to optimize and protect the entire service life of the transformer, which benefits all parties: manufacturers, EPCs and grid operators.

1 DESIGN AND PRODUCTION

The life of a transformer begins with its design and production. ETOS ® provides manufacturers with a preconfigured and tested system that is ready for connection and will cut costs by 65 % when compared with conventional automation. New digital business models, such as live support, are also possible. In addition, the data collected and experience gained in the field can be used to optimize future transformer designs.

2 DELIVERY AND INSTALLATION

After the transformer has been produced, it is sent to its destination. EPCs (Engineering-Procurement-Construction companies) perform the installation, during which up to 70 % on costs can be saved with the ETOS ® solution. This is because, instead of each sensor having many copper cables, just a single fiber-glass cable is used for connection to the monitoring system. The intelligence is located directly in the control cabinet on the transformer. In addition, data integration into a SCADA system is much simpler thanks to a standardized communication protocol (e.g. IEC 61850).

3OPERATION

After a transformer has been installed, it can be operated for decades. Networking makes it substantially easier to utilize the capacity and service life of the transformer. In this way, load and weather forecasts are transmitted via the control room directly to the transformer. This enables the transformer to automatically make decisions, such as when the cooling should be activated.

4CONDITION ASSESSMENT AND MAINTENANCE

During operation, asset-management and service personnel are responsible for performing maintenance, overhaul and modernization tasks on the transformer. They can use the data collected from the transformer to continuously monitor its condition and minimize failures. Calculations have demonstrated that online monitoring reduces the failure rate by 42 %.

5 STRATEGIC PLANNING

When should I invest in new equipment? Where should this equipment be used, and how should it be configured? Grid planners can use the data gained from the transformer for future load forecasts, and reduce the service-life costs of the transformer as a result. In addition, more precise requirement specifications can be sent to manufacturers for future investments.

YOUR CONTACT

Do you have questions about the MSENSE® sensor family and ETOS®?

Frank Micksch would be glad to answer your questions:

F.Micksch@reinhausen.com