How HIGHVOLT testing systems contribute to a successful energy transition — An overview.

OFFSHORE CABLE TESTING

OFFSHORE CABLE TESTING

They are growing in number and getting bigger and bigger: Offshore wind parks make a significant contribution to increasing the proportion of environmentally friendly electricity in the energy mix. At the same time, the generative performance of wind turbines is constantly increasing. For new wind parks, for example, the operating voltage of the connection cables from the wind turbines to the collection and connecting platforms is now being increased to 66 kV.

The experts at the International Electrotechnical Commission (IEC) therefore decided to permit — in addition to the SOAK test (a 24-hour test at nominal voltage) — only resonance testing for operating voltages greater than 36 kilovolts in the new standard IEC 63026 for submarine cables up to 72.5 kV.

HIGHVOLT is the only provider of a testing system that is weather-proof and therefore always available offshore despite adverse conditions.

MOBILE CABLE TESTING

MOBILE CABLE TESTING

HIGHVOLT is a pioneer when it comes to testing cables based on polymer insulating materials, such as cross-linked polyethylene (XLPE) in high-voltage applications. The engineers from Dresden built the first-ever mobile testing system, which fits on a semi truck trailer. It can therefore be transported to almost any location without special permits, even where there is no space for large testing systems.

This includes cities and densely populated regions where more and more cables are being routed underground. The testing trailer is designed for cable lengths of up to 10 kilometers; for longer cables, multiple testing systems can also be connected in parallel and in series.

HEALTH CHECK 120 M ABOVE THE GROUND

HEALTH CHECK 120 M ABOVE THE GROUND

Mechanical vibrations of the rotors, lightning strikes, frequent load changes and a high number of switching operations — the transformers in the nacelles of wind turbines are exposed to enormous loads. If they fail, it is a time-intensive and costly feat to repair or even replace them.

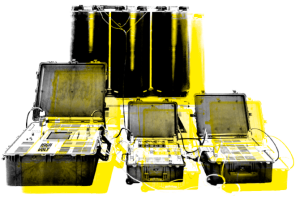

What can be done? Ideally, check the transformers regularly in order to identify impending damage at an early stage. The standard method for doing this is the induced voltage test with partial discharge diagnostics. But how does that work at more than a hundred meters above the ground, with little space in the nacelle? HIGHVOLT has developed a portable testing system that operators or service providers can use to inspect the condition of the transformer insulation directly in the nacelle itself.

XXL REACTORS FOR THE BACKBONE OF THE ENERGY TRANSITION

XXL REACTORS FOR THE BACKBONE OF THE ENERGY TRANSITION

Renewable energy sources are often far away from populated areas. Ever larger distances need to be traveled to transport the electricity to where it is needed. Projects with submarine and land cables of several hundred kilometers are therefore increasing around the globe. Prominent projects include the A‑Link, Südlink and SüdostLink in Germany, which form the backbone of the energy transition.

The cable sections must be tested in advance so that nothing goes wrong when operating these cable systems. The number one failure source are the joints that connect the cable sections to each other. Since conventional testing systems soon fall short in testing power, HIGHVOLT developed special XXL reactors. They provide four times as much power at only twice the volume of previous reactors for the resonance testing method. The power can be further increased through series and parallel connection, meaning that cable lengths of up to 200 kilometers can be tested.

OPERATION AT THE HEART OF THE ENERGY SUPPLY

OPERATION AT THE HEART OF THE ENERGY SUPPLY

Power transformers are reaching a critical age around the world, and at the same time, power grid loads are increasing due to bidirectional load flows caused by the supply of renewable energies. Operators can check whether the equipment needs servicing with tests such as the induced voltage test and loss measurements in a no-load state and under load.

Often, this necessitates dismantling the power transformer, draining the oil and then transporting it to a repair site — at significant logistical effort and expense. However, there’s an easier way.

HIGHVOLT has developed a testing system for this purpose that can be transported on a semi truck trailer, enabling this kind of high-voltage testing right in the primary substation. This way, the operator can decide based on the measurements whether removal is even necessary, or if cheaper on-site repairs will suffice.

BIG BROTHER IN THE CABLE DUCT

BIG BROTHER IN THE CABLE DUCT

When malfunctions occur during operation, the HiRES Locator can help. This online measuring device is connected to medium- and high-voltage cables during operation and locates a breakdown in real time, immediately raising an alarm.

As a result, operators know where they have to fix the problem. Conventional testing methods, in contrast, the fault is only located once the malfunction has occurred. Then, after the event, a suitable, powerful voltage source must be brought to the cable and measurements made in a costly and time-intensive procedure. The HiRES Locator is therefore a cost-effective solution for monitoring cable sections in real time.

IYOUR CONTACT

Do you have any questions about HIGHVOLT testing systems?

Thomas Steiner is happy to help you:

t.steiner@highvolt.com