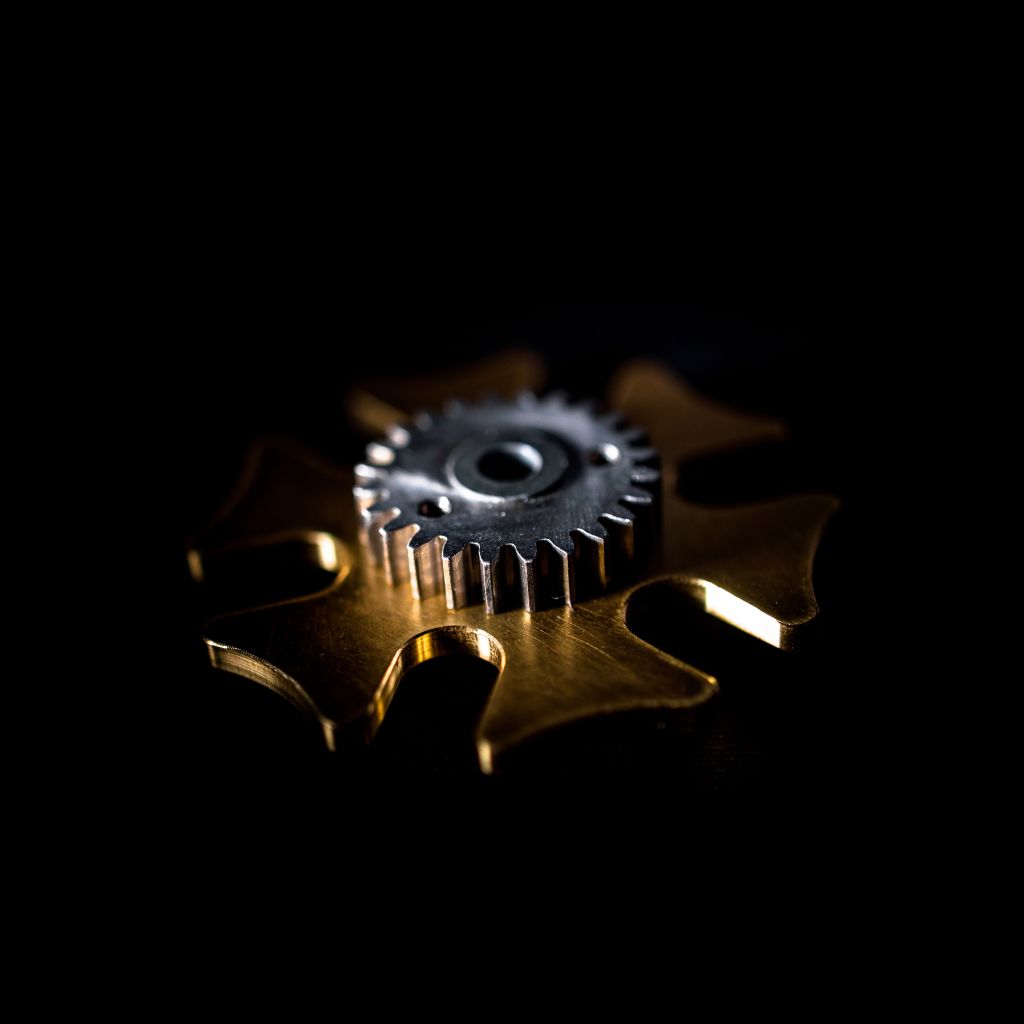

The Geneva wheel is at the heart of every tap changer: It regulates the tap-change operation by breaking down a uniform rotation into individual steps. This requires two elements: the slots and the external contour. The drivers engage with the slots and turn the Geneva wheel by a set angle. This is defined by the number of slots: if, for example, the 360-degree rotation is divided into sections of 40 degrees, this provides nine possible steps. The rounded areas on the outer sides of the wheel limbs, also known as the locking contour, prevent the wheel from continuing to rotate in an uncontrolled manner in the rest phases.

The Geneva wheel must work reliably for the entire life of the on-load tap-changer and must be absolutely wear-proof. That is why we design and produce all metallic Geneva wheels ourselves. Reinhausen’s largest Geneva wheel has a diameter of over 81 centimeters. It is fitted in the OILTAP® G. This one here measures just 5.5 centimeters and is found in the control gear of the smallest tap changer in the world, the ECOTAP VPD.

In the ECOTAP VPD, the Geneva wheel is not in oil, so the requirements regarding corrosion resistance are high. That’s why we use a special brass alloy.