Power Composites (PC) has opened a new plant for hollow composite insulators in India. In this interview, Executive Director Business Development and Sales Marcus Hartmann speaks about the site, the joint venture with Aditya Birla, and the benefits for customers.

Why did Power Composites decide to open a new site in India?

India is one of the countries with the strongest economic growth. But so far there is no local manufacturer for hollow composite insulators despite the high demand that the Indian market has for these components. Together with our local partner Aditya Birla, we aim to satisfy this demand in the future. Our new Aditya Birla Power Composites Ltd. plant in the city of Halol, Gujarat, represents our first major step toward growth in that direction.

What led you to form a joint venture?

It isn’t easy for European companies to gain access to the important Indian market because the customers there prefer local products. So it was clear to us from the beginning that we could only gain market entry by working with a strong, local partner.

And that’s Aditya Birla?

Yes! With turnover of around EUR 50 billion, Aditya Birla is one of the largest groups on the Indian market and is the country’s leading manufacturer of porcelain insulators. The business is highly diversified and boasts extensive technical expertise, plus wide customer reach. Furthermore, Aditya Birla has very high quality standards and is held in high esteem both in Indian society and on international markets.

Aditya Birla

With turnover of USD 48.3 billion, the Aditya Birla Group is in the Indian league of Fortune 500 companies and employs over 120,000 people in 36 countries. With a history spanning over 70 years, the Group has contributed to the upturn in the Indian economy and has helped to shape society through its high level of social engagement. Through its subsidiaries, the Aditya Birla Group is represented in a range of different economic sectors — including metals, textiles, carbon black, telecommunications, cement, and insulators.

With turnover of USD 48.3 billion, the Aditya Birla Group is in the Indian league of Fortune 500 companies and employs over 120,000 people in 36 countries. With a history spanning over 70 years, the Group has contributed to the upturn in the Indian economy and has helped to shape society through its high level of social engagement. Through its subsidiaries, the Aditya Birla Group is represented in a range of different economic sectors — including metals, textiles, carbon black, telecommunications, cement, and insulators.

What do you hope to gain from the joint venture?

We want to carve out an even stronger position for ourselves in large-scale bulk business in comparison to our major Chinese competitors and offer customers in this segment high-quality products at competitive prices. This is a crucial factor, particularly on the Indian market, given the significant increase in energy demand it is showing.

And on the global market?

Our aim here is to be the top player in the global market for hollow composite insulators and continue to serve as a reliable development partner for our customers when it comes to technology and quality, even more so than we have been in the past. With this joint venture, we are taking a major step toward achieving this goal, and this is allowing us to counter the aggressive competition we are facing from other parts of Asia.

“We now have all three manufacturing technologies at our disposal — allowing us to cater to all pricing segments.”

What makes you so confident about that?

We now have another unique selling point on the market: In India, we are producing our hollow composite insulators with HTV injection technology for the first time. This means that we combine all three shielding technologies under one roof at Power Composites, along with LSR injection and HTV extrusion. Nobody else can claim to do that. We can now cater to all requirements in all global markets. As a full-service supplier, this makes us highly interesting to both national as well as international customers.

And what does the customer get from this?

We can now truly meet all demands and communicate a very promising message to customers worldwide—no matter the requirements or the supply region, we have what it takes to accommodate anything, and we’ll do so with outstanding technical expertise and standardized manufacturing processes.

Will your other sites also benefit from the joint venture?

Absolutely. Ultimately, we are not just catering to standard bulk business via the Indian market. It is also a way of gaining new customers to whom we hope to supply our premium products and support over the long term. This makes our Indian site the perfect addition to our existing portfolio, not just an additional means of accessing the market.

“The joint venture is a real mix of the core values of both companies. The technological edge and the specialist knowledge on both sides will create a visible synergy. In this way, we will be able to cater to the demand for insulators in the energy equipment industry and help Indian and international OEMs to improve their product portfolio for transmission and distribution network facilities around the world.”

Sanjeev Sachdev, CEO of the joint venture Aditya Birla Power Composites Limited

What does the future look like for the joint venture?

Very positive—I have high hopes for it. The demand for hollow composite insulators is still experiencing strong growth both on the Indian as well as the global market. And a high level of interest among our customers is already reflecting that. We are therefore keen to further strengthen our professional and cordial partnership with Aditya Birla.

Perfect shielding

Reinhausen Power Composites uses these three methods for shielding hollow insulators.

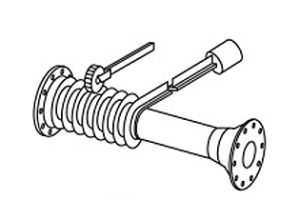

The high-temperature-vulcanizing (HTV) extrusion process

This process is used at the Cusset site in France. An extruder applies silicone to the GFRP tube. This process is particularly suitable for complicated shielding profiles; for example, those for high-voltage direct current transmission applications.

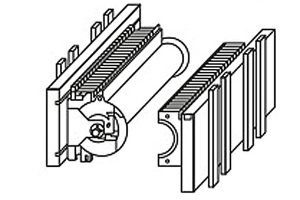

The Liquid silcone rubber (LSR) shielding technology

The LSR-Injections molding technology is used in Regensburg. This process involves pressing liquid silicone into molds at high pressure. LSR technology is particularly suitable for producing highly standardized insulators in large quantities

HTV injection moulding technologie

This technology is used at the new site in Halol in India with the tried-and-tested Power Composites design and quality processes. The manufacturing principle is similar to the process for LSR shielding technology. However, rather than liquid silicone, higher-strength HTV silicone is pressed into molds under high pressure. HTV injection molding technology is particularly suitable for producing standardized products such as voltage transformers and circuit breakers in large quantities.

YOUR CONTACT

If you have any questions about shielding technology, please contact Marcus Hartmann: M.Hartmann@reinhausen.com