How long will our transformers last? This question is faced by more and more grid operators around the world whose fleets are becoming increasingly dated. Previously, the decision to replace a transformer was often exclusively based on its age, regardless of its actual condition. With a new method, this will all change.

Jan Patrick Linossier and Rolf Funk have racked their brains over the so-called „bathtub curve“many times already. Both are responsible for strategic asset management at the „Rheinische NETZGesellschaft“ (RNG), Rhineland‘s electricity grid operator, and are therefore tasked with assessing the condition and risk factors of the equipment in use. This includes around 100 power transformers which the distribution system operator manages from Cologne for an electricity grid spanning roughly 20,000 kilometers. „We have to know the exact condition of our transformers. Whether they‘re still serviceable or whether we need to invest in new ones is a question we are constantly faced with. The problem is, nobody in the industry knows exactly how long a transformer will ultimately last,“ explains Linossier, who heads up strategic asset management at RNG.

MORE FREQUENT FAULTS IN AGING TRANSFORMERS

The bathtub curve is a model for describing the susceptibility of equipment to failure over its entire service life. Just after commissioning, the failure rate is very high. Once the initial problems have been fixed, the failure rate drops rapidly and hovers at a constantly low rate. For a long period of time, this doesn‘t change. But as the system gets older, the problems start to stack up again after a certain point. If you represented this trend as a graph, with time along the X‑axis and the failure rate along the Y‑axis, the curve would look something like the cross-section of a bathtub.

But what Linossier and Funk have been racking their brains over is the following: At what point of the bathtub curve are their transformers currently at? When does the failure rate start to climb again? „That is the point at which we should be arranging a replacement,“ says Mr. Funk, who specializes in strategic asset management for power transformers. Since the average age of transformers at RNG is 45.7 years, this question is becoming increasingly pressing. Most of these transformers were commissioned back in the 1950s and 1960s. The decision to replace these transformers not only has technical ramifications, but also has financial considerations as well, since a new power transformer of this scale would cost almost half a million euros. „Previously we would simply replace the transformers with new ones after a certain amount of time, but the cost pressures today are much higher. For this reason, we want to get the most out of the equipment for as long as possible,“ says Mr. Linossier.

„There are transformers used in industrial fields which have to replaced after 15 years of usage, and then there are those which only operate at 30 percent load and have been in operation for over 50 years already. So the transformer‘s age alone doesn‘t necessarily say anything about its condition.“

Alexei Babizki

And RNG isn‘t the only operator with a fleet of aging transformers: In the two decades following the Second World War, the demand for more and more electricity increased rapidly. New power plants were built, cables were laid, and numerous primary substations were erected. Huge swaths of the German electricity grid today are still based on the plans drawn up during this time. And this was not limited to Germany, but was rather a phenomenon of all modern industrial nations. That said, the network load forecasts at the time were much different.

„With the increasing use of renewable energies, grid structures need to be completely redesigned and it‘s therefore very important that we know the exact condition of our transformers,“ stresses Mr. Linossier. On the one hand, because the utilization of the transformers changes over time and, on the other, because upgrading the network will make some installations redundant in the future. „If we replace the transformers too early, that could turn out later to be a bad investment,“ adds Mr. Funk. At present there is no method for assessing the exact condition of the transformer fleet.

COLLABORATION ON THE TRAM

However, all this is set to change thanks to a chance encounter in a tram in Lyon. Alexei Babizki, Portfolio Manager at MR and Markus Zdrallek, a professor at the University of Wuppertal, got into a chance conversation on the way to the airport, both having just attended the same congress. Zdrallek holds the senior professorship for electrical energy supply technology and has been working on the condition assessment of equipment in electricity grids for many years. „We want to offer grid operators a scientific basis for intelligent network renewal strategies,“ says Mr. Zdrallek, „but power transformers have not yet been examined in my research.“

KEEPING THE FLEET IN VIEW – HOW IT WORKS:

The condition of the transformers is examined in up to three stages, which can reduce the required downtime of the transformers:

1 In the first stage, the operator provides the data which is already available. This includes, for example, the age of the transformers, measurements that have already been carried out, and maintenance history information.

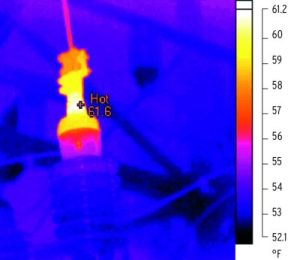

2 The second stage involves an on-site appraisal which is carried out while the transformers are still in operation. In the visual inspection, an expert uses a checklist to examine the transformer based on its external characteristics: Are there any signs of corrosion or leaks? Is there visible damage to the bushings or fans? How old is the motor-drive unit? For the measurements, thermographic tests are performed and oil samples are taken.

3 If, after this stage, there are any indications of more significant damage, the third examination stage will follow. In this stage,extensive measurements are performed, including a dynamic resistance measurement and partial discharge measurement. However, to carry out these tests, the transformer must be removed from the grid.

The data collected using this method is evaluated. The analysis is carried out using the algorithm developed at the University of Wuppertal in association with MR. Then the data is transferred into two indexes, with one revealing information about life-time wear and the other about the failure rate. For the assessment, the results of the two indexes are transferred into one graphic. The condition of the transformer fleet can thus be visualized simply; the more transformers located in the quadrants near the origin, the better the condition of the fleet and vice versa.

This immediately aroused the interest of Mr. Babizki, since he was looking for a system for determining the condition of power transformers. He also knows that this helps provide an important service for MR‘s customers: „It‘s impossible to give a general answer to the question of how long a transformer will last. There are transformers used in industrial fields which have to replaced after 15 years of usage, and then there are those which only operate at 30 percent load and have been in operation for over 50 years already. So the transformer‘s age alone doesn‘t necessarily say anything about its condition,“ explains Mr. Babizki. He and Mr. Zdrallek quickly agreed that this would be the ideal topic for collaboration.

„It is of strategic importance for us that we know the exact condition of our transformers.“Jan Patrick Linossier

„We didn‘t have the well-grounded understanding of transformers we needed, but we did have extensive expertise in the development of condition assessments,“ recalled Mr. Zdrallek. The researcher hopes that the project will shed more light on how transformers deteriorate over time, since he is also interested in the bathtub curve. „The curve is often described in the theoretical literature and has even been proven for some elements of electronics. But I was skeptical of whether the curve even exists for electrical grid components, and more specifically for transformers, because nobody has yet managed to prove this,“ adds Mr. Zdrallek. And thus began the collaboration between the two partners. In a series of meetings and workshops, they worked together to develop an assessment system.

LONGEVITY AND FAILURE RISK IN FOCUS

What was still lacking, however, were transformers on which they could test their assessment system. Mr. Zdrallek thought immediately of RNG, with which he had already completed numerous projects. Linossier and Funk didn‘t have to think about it for long: „The approach seemed very promising to us, so we immediately agreed to collaborate in a pilot study,“ says Mr. Linossier. What made this approach special is that the system (see box below) regards the transformer from two perspectives. On the one hand, there is the long-term view which focuses on longevity and is thus important for investment decisions. And on the other hand, there is the short-term view which is targeted at the risk of failure, and influences decision-making relating to maintenance.

All the main components of the transformers are examined carefully, from the on-load tap-changer and motor-drive unit to the cooling fans. A total of 200 parameters ultimately influence the outcome of the assessment, including maintenance history data and results from on-site measurements. The collected data is then analyzed using a special algorithm. „There are many indicators we can use to ascertain the condition of the transformer. If, for instance, the thermographic measurement shows that a particular area of the transformer is hot, it is possible to localize the fault. Then detailed measurement methods are required,“ explains Mr. Zdrallek. Another crucial element for the assessment is the oil analysis, which can be carried out by MR in the laboratory of its subsidiary Messko. As Mr. Babizki makes clear, „it‘s a bit like doing someone‘s blood-work at the lab, where an increased white blood cell count might indicate an infection, for example. Similarly, for transformer oil, a higher acetyl value is an indication of electrical arcing, which may be a sign that the transformer is in poor condition.“

AN INSTRUMENT FOR OBJECTIVE FLEET EVALUATION

RNG provided nine transformers for the pilot study. „Our choice of transformers reflected a representative sample of our fleet,“ explains Mr. Linossier. After extensive tests and subsequent analysis, the results were in: All transformers were found to be in good condition. For some units, the risk of failure could even be reduced with simple measures, thus extending their service life. „That‘s the advantage of the method we have developed. Not only do we offer our customers a condition assessment, but also recommendations for corrective action,“ emphasizes Mr. Babizki.

The partners also take special cases into consideration. For example, in one transformer a high acetyl value suggested there was a problem. As Mr. Linossier stresses, „MR pointed out that this value can vary depending on model.“ The limit-value being exceeded in the transformer oil was therefore trivial, which made renewal unnecessary. „We designed the algorithm to take into account the type of tap changer used,“ adds Mr. Babizki.

Mr. Zdrallek is also happy with the new method: „It is exciting to me from a scientific point of view. If many network operators start working with it, then we might be able to use the mass of collected data one day to find out whether the bathtub curve is actually real.“ In any case, RNG has decided to use this method to examine the majority of its fleet of transformers. „We now have an instrument for objectively evaluating the condition of our fleet. This is an enormously im portant development for our strategic decision-making,“ underscores Mr. Linossier.

Learn more about this collaboration in an interview with Jan Patrick Linossier and Markus Zdrallek.

YOUR CONTACT

Would you also like to apply the new method to assess your fleet of transformers?

Alexei Babizki is available for your questions:

a.babizki@reinhausen.com