Intelligent transformers support operation and help with their own maintenance. Reinhausen provides the appropriate modules – from individual sensors to fleet monitoring – at all three automation levels.

1. Process level:

Sensors and protective devices on the transformer

The sensors and protective devices on the transformer collect the data required for automation. Reinhausen provides a broad portfolio of measuring technology in the form of the MSENSE® products from its MESSKO subsidiary. However, the system is also open to components from other manufacturers.

Conventional sensors

The MESSKO® COMPACT, MESSKO® TRASY2, and MESSKO® Betech series are used to measure the oil and winding temperatures. The MESSKO® MTO and MESSKO® MMK oil-level indicators monitor the fill level.

Intelligent sensors

The MSENSE® DGA monitors the gas content in the oil, while the MSENSE® BM monitors the status of the capacitance graded bushings. The MESSKO® MTeC EPT303 FO measures the winding temperature directly at the source.

Protective devices

The protective devices enable fault-free operation and provide important data. They include the MESSKO® MTraB® dehydrating breather and the MESSKO® MSafe® Buchholz relay.

Open to sensors from other manufacturers

Sensors from third-party manufacturers can easily be connected to ETOS® via standardized interfaces.

2. Field level:

Control, regulation and monitoring directly on the transformer

ETOS® forms the heart of the digitalization solution: The combination of hardware components and software serves as the interface between the process and control levels. This is where all of the data from the transformer comes together to be analyzed and evaluated using algorithms developed by Reinhausen or, alternatively, customers’ own algorithms. The open standard for digitalization can be used for transformers from all manufacturers regardless of age or power class — for a single transformer or an entire fleet.

ETOS® is available in a range of designs and housing types — in the form of pluggable modules, a stand-alone version in a control cabinet, or an integration solution in a motor-drive unit, depending on the requirements. Fitting ETOS® directly on the transformer allows the captured data to be transferred to the control station via network protocol using a fiber-optic cable. This greatly reduces the amount of wiring needed during installation and significantly cuts costs compared to a conventional connection method.

Modular structure

There are six modular function packages to choose from depending on the monitoring requirements.

Transformer monitoring

On-load tap-changer monitoring

Online DGA monitoring

Control and monitoring of the cooling system

Bushing monitoring

Automatic voltage regulation

Cybersecurity

Hacker attacks on power networks represent a real threat in today’s society. IT security was therefore the top priority even in the early stages of developing ETOS®. The result is a state-of-the-art solution that covers everything from product architecture to support. The product features include an integrated firewall, encrypted communication, and role-based access control. The process features include external auditing and product security management by a dedicated CERT team. The system continually monitors the electronic components for potential vulnerabilities and provides the customer with simple security updates.

3. Control level:

Superordinate visualization and control of the transformer fleet

TESSA® — The fleet monitoring solution from Reinhausen

For operators of electrical energy networks, it is crucial to know the precise status of their transformer fleet. ETOS® provides all of the necessary data for each transformer. TESSA®, the fleet monitoring solution developed by Reinhausen, combines this data into an overall picture, making it an intelligent tool for monitoring all equipment. Thanks to its real-time monitoring, maintenance intervals can be extended and on-site system inspections reduced. With the early warning system, operators can respond immediately when a fault is identified. This prevents costly repairs.

SCADA and cloud systems

If desired, operators can also integrate the data and information into existing SCADA systems and all standard cloud systems. This is possible thanks to the open, standardized interfaces provided by ETOS®.

If desired, operators can also integrate the data and information into existing SCADA systems and all standard cloud systems. This is possible thanks to the open, standardized interfaces provided by ETOS®.

Pushed to the Limits

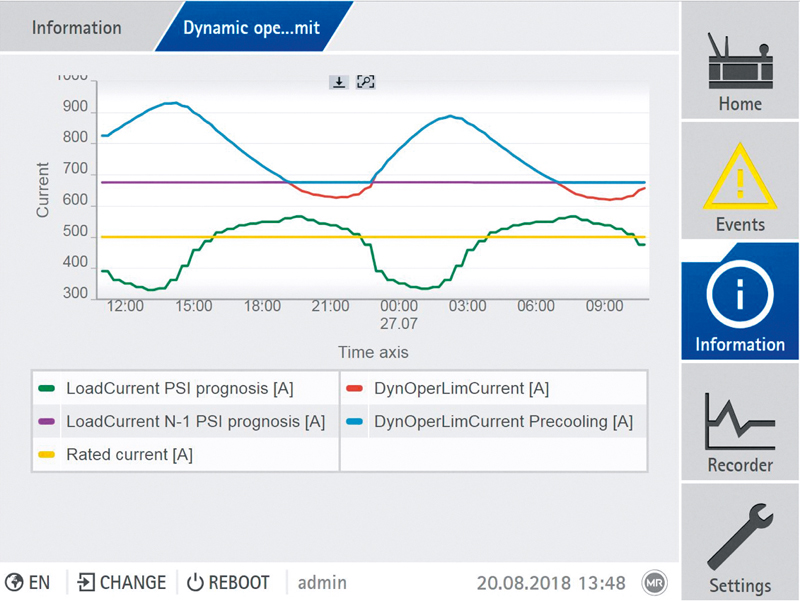

The open nature of ETOS® also enables new business models. PSI Software AG uses the system for a digital solution that enables network operators to utilize their transformers more efficiently.

In energy networks, bottlenecks are one of the daily challenges that operators have to deal with. In order to ensure that the supply remains reliable, what is known as a redispatch is required in these cases. This involves generators increasing or decreasing their electricity production as necessary, resulting in considerable costs for the network operators. Through intelligent network control and the use of detailed equipment information, these interventions can be reduced and equipment can be utilized more efficiently. Through the combined efforts of PSI and Reinhausen, transformers can be operated more efficiently with ETOS® and redispatch costs can be minimized.

YOUR CONTACT

Would you like to know more about ETOS®?

Tobias Gruber is happy to advise you further:

t.gruber@reinhausen.com