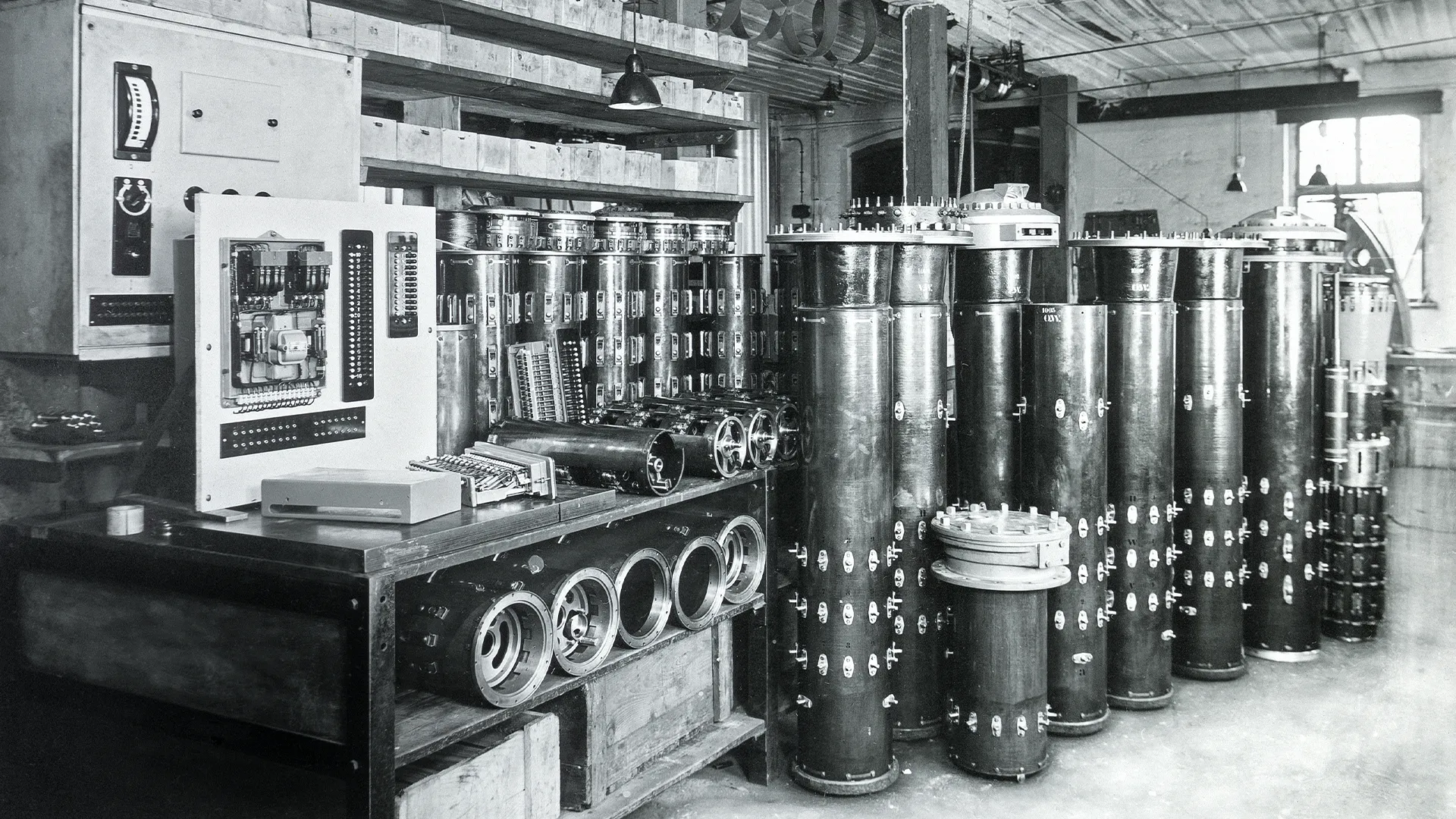

100 years ago, the invention of the high-speed resistor-type tap-changer by Dr. Bernhard Jansen made it possible for the first time to switch transformers under load. Reinhausen brought this groundbreaking invention to global markets under the MR brand, thereby helping to shape the energy industry as we know it today, with a comprehensive, voltage-stable power supply. In this interview, managing directors Dr. Nicolas Maier-Scheubeck, Holger Michalka, and Wilfried Breuer explain how this legacy will continue to have an impact far into the future.

Dr. Maier-Scheubeck, Mr. Michalka, Mr. Breuer, Reinhausen will celebrate the 100th anniversary of the high-speed resistor-type tap-changer in 2026. How do you personally view this anniversary?

Scheubeck: For me, this anniversary represents a leap forward–from product to solution. Since its invention, the high-speed resistor-type tap-changer has become established at all voltage levels and has become a guarantee of supply security. During this time, electricity has become a factor in prosperity–a development that our company has played a key role in shaping. We want to raise awareness of this even more in our anniversary year. Our message to employees, customers, and partners is: We serve people by ensuring a reliable, economical, and sustainable supply of electricity with our innovations, now and in the future.

Michalka: The invention of the high-speed resistor-type tap-changer was revolutionary and remains the foundation of our success to this day. I am particularly fascinated by the pioneering spirit of that time–and the fact that it lives on in our company. For us, quality, innovation, and customer focus are both a commitment and an incentive.

“Our claim is genuine innovation—by which we mean not minor changes, but solutions that the market has not yet seen.”

Dr. Nicolas Maier-Scheubeck

Breuer: I see the tap changer more through the eyes of an engineer. It is a groundbreaking invention, comparable to Carl Benz’s first motor car or Thomas Alva Edison’s light bulb. Although it is not as visible because it is hidden inside the transformer, the highspeed resistor-type tap-changer was just as influential for our industry. Its 100-year success story proves that this invention was hugely significant and also future oriented.

Making a groundbreaking invention is one thing, but how do you ensure that its success is sustainable as a company? What is your recipe for success?

Scheubeck: One very important factor is that we are still a family-owned company in the sixth generation. If we were listed on the stock exchange, we would not be able to do what we have been doing for the industry for decades. Our independence allows us to stick with solutions even if they do not appear to be economically viable at first. Let me give you an example: More than eight years ago, we introduced the ECOTAP® VPD®, a tap changer for the lowest voltage level. We had previously conducted studies on grid development, but at that time no one was thinking about regulated distribution transformers. Today, it has already become a standard in distribution grids. We have staying power, and that is exactly what makes the difference.

Breuer: I can only confirm that. From the customer’s point of view, trust plays a major role. Our partners often tell us: You are a reliable port in the storm. While others change their corporate structures, we remain stable and focused on the long term. And internally, I feel that the passion here is extraordinary–going the extra mile is not the exception, but the standard. This is strongly linked to our family tradition.

Michalka: And for our employees, it means that we can give success a fair chance. We have the freedom to believe in a technology or an application–and to pursue it even when others would have given up long ago. This independence is a real driving force for all of us, and long-term thinking is deeply rooted in our values. That is the basis of our innovative strength.

Innovation is a recurring theme throughout Reinhausen’s history. What do you understand by innovation?

Scheubeck: Our aim is to create solutions that are as substantially new as Dr. Jansen’s invention was at its time. This innovation understanding is part of our values and the time factor plays a decisive role here. And in this respect, we differ significantly from other companies that focus on short-term success through simple developments with little novelty value, or even on imitation. We take the time to create something truly new.

Michalka: For us, the courage to engage in “constructive self-destruction” is always part of the process. We don’t rest on our laurels, but rather keep questioning ourselves until we find a better solution. That’s the only way to remain the market leader.

What are the latest products that have emerged from this spirit?

Breuer: Definitely the new VACUTAP® VI. With this tap changer, we have implemented the principle of the high-speed resistor-type tap-changer in a minimalist way. We were able to halve the amount of material required, thereby creating flexibility in production. It was developed specifically for the grid connection of renewables, where cost-effectiveness is crucial, but sustainability and consistently high reliability are also playing increasingly important roles.

Michalka: To achieve this, we have deeply rethought the VACUTAP® VI from the customer’s perspective–and that is precisely where a small revolution lies. Less material means a lower carbon footprint–in production as well as throughout the entire value chain, right through to subsequent recycling. And yet the quality standards remain high.

The energy transition poses enormous challenges for the energy industry worldwide. Grids are being rebuilt, and infrastructure is becoming more complex and can only be managed with the help of digitalization and AI. How is Reinhausen prepared for this?

Breuer: We have been the market leader in tap changers for 100 years – and we intend to remain so. Fast followers may copy us, but we constantly reinvent ourselves and continue to correctly anticipate market developments which are becoming increasingly diverse on a regional basis. China is a continent unto itself, industrialization is growing in Southeast Asia, and the US is distancing itself politically. Our response to these situations is to increase our local presence.

Because customer proximity is part of our values, we are already very well prepared for this with currently 44 affiliated companies in 28 countries. Our Power Quality business segment also makes a significant contribution to the energy transition by filtering out the non-linear, disruptive influences caused when output from wind farms and solar plants are fed into the grid via power electronics. And with HIGHVOLT’s cable testing technology, we increase the operational reliability and availability of HVDC lines of more than 500 kV, such as for SüdLink in Germany.

“The tap changer is a groundbreaking invention—comparable to Carl Benz’s motor car or Edison’s light bulb.”

Wilfried Breuer

Michalka: Together with our customers, we are shaping the energy transition. This is firmly anchored in our strategy, describes how we want to change in order to master global challenges, and involves our employees in all regions of the world.

Scheubeck: It is important that we continue to move consistently from products to solutions. Today, we understand not only the transformer, but also its role in the entire grid. And with our solutions for digitalization and for asset performance management, we help our customers to work more economically while compensating for the shortage of skilled workers.

Due to the global expansion and restructuring of networks, the demand for energy technology is enormous. Reinhausen is also growing rapidly. How are you setting up production for the future?

Scheubeck: As the market leader, we were the first to feel the wave of increased demand, and our capacities were exhausted very quickly. In response we have expanded rapidly and are continuing to do so consistently–also on a regional basis–in order to further shorten delivery times and ensure material availability. From our customers’ perspective, these measures are already having the desired effect, and we will continue to do more in the future.

Michalka: We have therefore just launched the largest investment program in our company’s history–with a three-digit million Euro amount. For example, we are doubling production capacity in Germany and quadrupling it in China. This will enable us to continue to efficiently meet the rising demand in the super cycle of the global energy transition in the future.

Breuer: Another unique selling point is that we can maintain even decades-old tap changers and further extend their service lives. Quality, reliability, and sustainability remain our hallmarks, even in times of high growth.

The energy transition can be seen as the world’s largest sustainability project. What is Reinhausen itself doing to promote sustainability?

Scheubeck: Our products are designed for decades of use and maximum reliability. This makes it difficult to change materials at short notice, which may be necessary, for example, due to changes in legal requirements. In this respect, sustainability for us means above all thinking ahead with comprehensive responsibility for decades to come.

Breuer: There is often a lack of clear rules, so in the context of product development we have to decide today which materials will still be permitted in ten or more years’ time. In this regard, the short-sightedness of politicians is more of a hindrance than a help. We also weigh up CO2 reduction and recyclability very carefully–but always with a view to ensuring the secure operation of our products.

“The high-speed resistor-type tap-changer was a revolution—and it remains the foundation of our success.”

Holger Michalka

Michalka: For us as a family-owned business, sustainability has always been a matter of course. We use natural resources carefully–from low-emission painting facilities to photovoltaics and LED conversions. We take responsibility, not because it’s fashionable, but because we only have this one world.

Finally, let’s take a look into the future: Where do you see Reinhausen in 2030?

Scheubeck: By then, our perception will be multi-regional. In addition to physical solutions, software, analysis, and remote maintenance will play greater roles. Our industry is not innovation-oriented, but rather safety-oriented. However, due to the changes brought about by the global energy transition, many companies now have to adopt new solutions more quickly. And that is precisely our advantage: we have already developed many of these solutions before they were even in demand. We are actively shaping the market–we’re not waiting for others to do something, but are driving development ourselves. In the future, our customers will challenge us even more in areas such as operations management, consulting, and remote control. In addition, we are expected to have an even more competent local presence and to enable others to make the best possible use of our technical solutions.

Breuer: Despite globalization and technological advances, our deep roots in Regensburg will remain intact as a Bavarian family-owned business.

Michalka: Looking at the Regensburg site, I envision a digital customer experience center by 2030, where we will discuss the future of energy in 3D simulations. And in Haslbach, I see a state-of-the-art factory with collaborative robots and AI-controlled processes.