Reinhausen subsidiary HIGHVOLT is now also establishing its resonance testing method in the medium-voltage range. This ensures greater security in grid operation.

A tiny grain of sand is enough to plunge an entire city into darkness. If even the smallest particles of dirt get into the connection sleeves when laying power cables, a violent flashover can occur under operating voltage. Not only do parts of the energy supply system collapse, but cable sections and connection sleeves are also destroyed and must be replaced. But how can this be prevented? Defects in the insulation and connection sleeves are not visible to the naked eye. Over the last three decades, the resonance testing method has established itself as a reliable and proven principle for inspecting cables for faults before commissioning, but also during routine checks or after repairs.

HIGHVOLT first developed a mobile system for on-site testing back in the 1990s, thereby establishing the method. The procedure involves applying a test voltage and, at the same time, performing a partial discharge measurement. This serves to detect discharges in the cable that could lead to a breakdown. In this way grid operators can eliminate faults before the cable is connected to the grid. Until now, the process has only been used at high and extra-high voltage levels, but that is about to change. HIGHVOLT has developed a new mobile testing system that is suitable for both medium voltage and the lower high-voltage level. Michael Hensel, Senior Sales Engineer at HIGHVOLT, explains: “The special feature of our system is that it covers a very wide range with a test voltage of up to 75 kilovolts.”

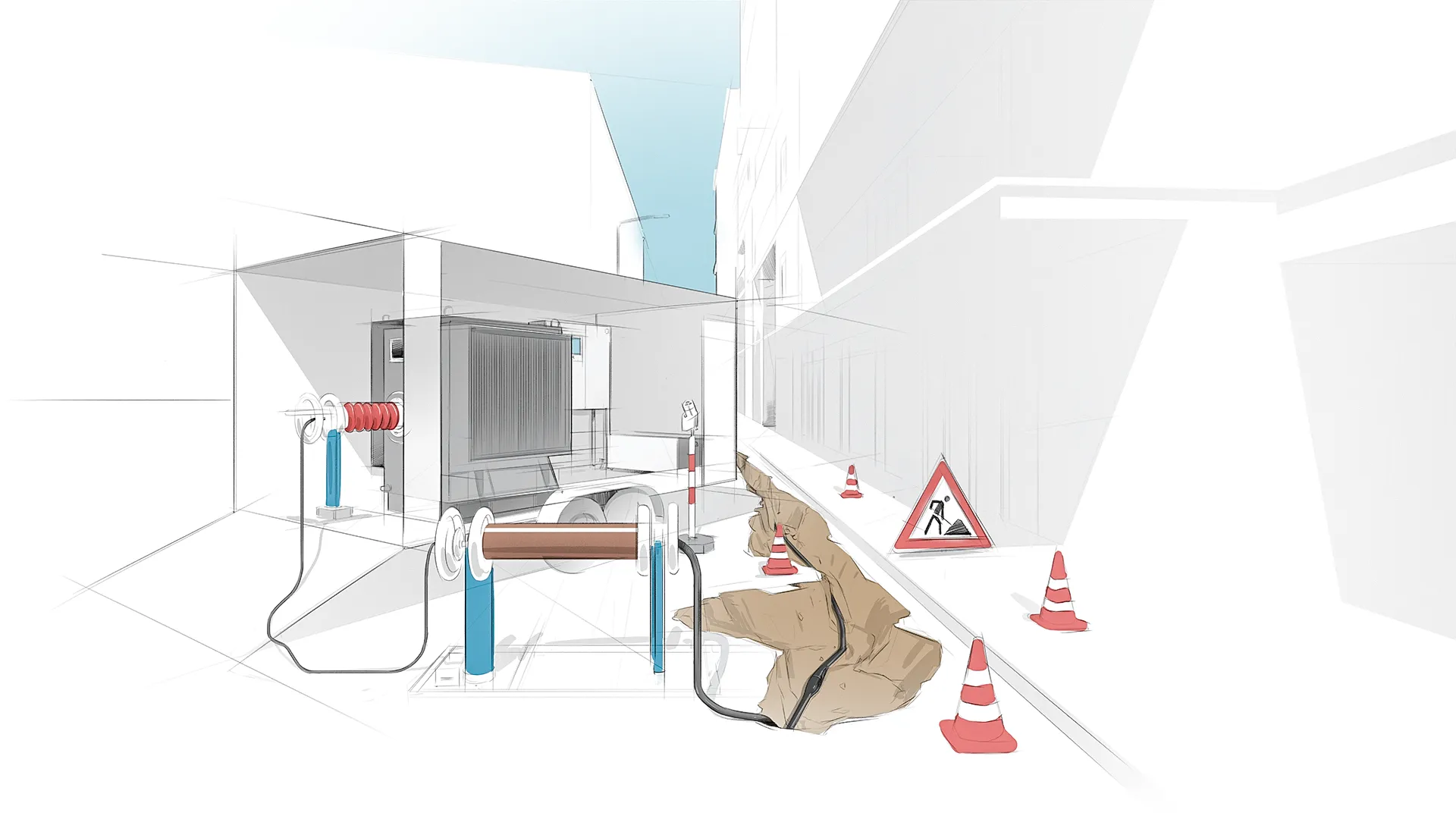

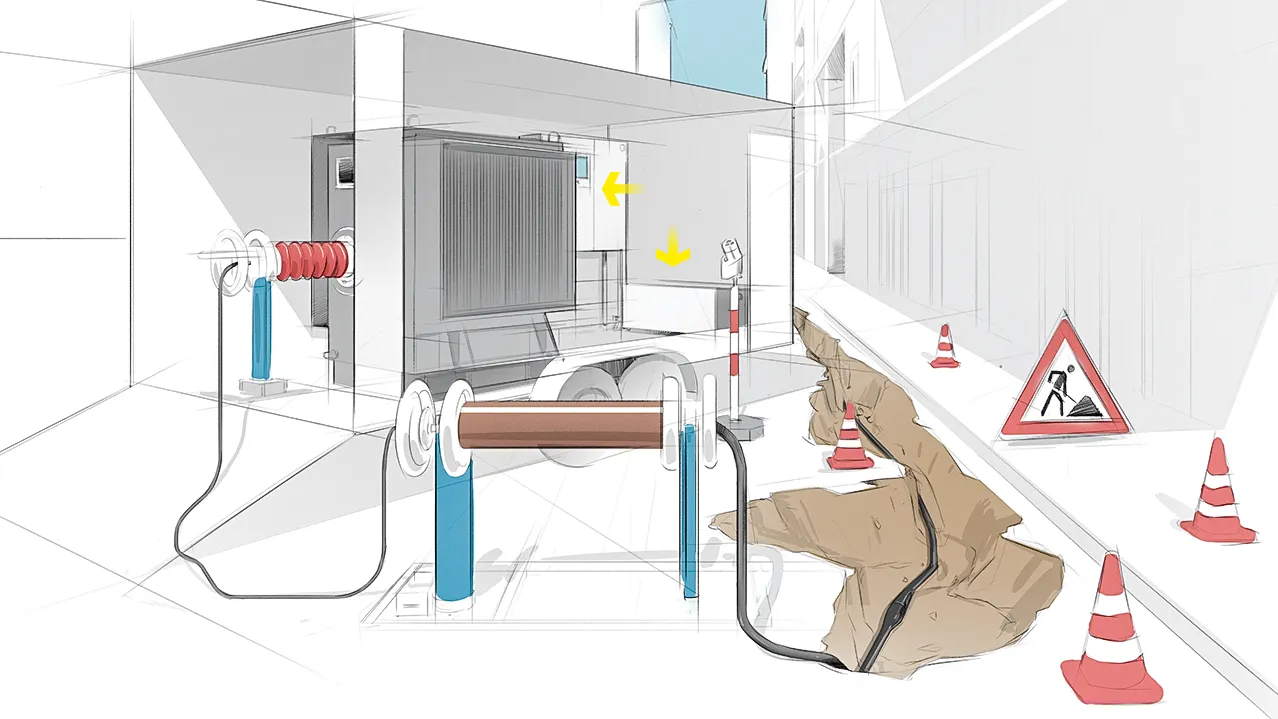

Compact cable tester

The resonance testing system for medium-voltage cables is designed for a test voltage of up to 75,000 volts and fits on smaller trucks and trailers.

Click on the -symbols for more information on the areas.

Medium voltage under pressure

In medium voltage, the so-called very low frequency (VLF) test has been the standard method for testing cables. As the name suggests, these systems operate with a very-low-frequency alternating voltage of just 0.1 hertz. The advantage is that this method does not require high test currents, which means that the test equipment can be small in size. But the method also has its pitfalls, as Hensel explains: “For testing, a test frequency is used that does not correspond to real conditions at all. Depending on the country, the mains frequency is 50 or 60 hertz, so testing at 0.1 hertz means there is a risk that faults will not be detected at all.”

“A testing system should be as close as possible to the real operating conditions in the grid.”

Michael Hensel, Senior Sales Engineer at HIGHVOLT

Since the insulating medium behaves differently depending on the frequency, it is also possible that problems may be indicated at a low frequency that would never occur in normal mains operation. “Therefore, a system that comes as close as possible to real conditions is more suitable. Our test systems, which have been in use worldwide in high and extra high-voltage applications for 25 years, have proven that they are capable of doing this,” says Hensel. Reliable fault detection is also becoming increasingly important in medium voltage, in particular because the expansion of renewable energies places heavy demands on medium-voltage cables. However, the test systems that HIGHVOLT builds for high and extra-high-voltage are too large for these cases, because medium-voltage cables are usually located in places that are difficult to access with a large truck.

Small reactor, big performance

The engineers at HIGHVOLT therefore redesigned the system so that it does not exceed a total weight of 3.5 tons and can thus be transported by a small truck or trailer. The most important lever for achieving this is the resonance reactor, which provides the test voltage. This is no easy task, as the reactor must remain thermally and mechanically stable throughout the entire one-hour test process without deformation or overheating.

“We have the expertise to implement such compact designs–not everyone can do that,” says Hensel. The reactor that HIGHVOLT has designed for the system is not only compact but also flashover-proof. This means that, unlike for larger systems, no additional protective measures are necessary. One customer from the US and another from Asia are already using the new test system. “So far, we haven’t had any feedback–that’s a good sign,” smiles Hensel.

YOUR CONTACT

Do you have any questions about the medium-voltage test system?

Michael Hensel is here to help:

M.Hensel@highvolt.com