Stahlwerk Thüringen GmbH (SWT) needs a new solution for compensating reactive power and harmonics. The GRIDCON® STATCOM MMC system from MR Power Quality is perfect for this task!

There are rumbling and hissing noises in the production hall in Unterwellenborn, Thuringia where enormous forces are at work when the 1,250-degree, glowing red steel blocks are driven back and forth through the rolling mill until they have the desired thickness and shape. Stahlwerk Thüringen GmbH (SWT) produces more than 800,000 tons of steel per year, which is used worldwide in the construction industry, for bridges and railways, but also in offshore wind farms. To meet the various requirements, SWT has over 250 different profiles in its range, all of which are made from 100-percent recycled scrap.

The large drives that propel the steel through the rollers perform heavy-duty work, which also affects the power grid—at least if SWT does not take preventative action. Problems may arise since the motors need substantial reactive power to manage ongoing acceleration, braking, and changes in direction. Added to this are harmonics generated by the operation of powerful speed-controlled rolling mill drives.

“We developed our GRIDCON® STATCOM MMC system specifically for industrial plants. Problems like those encountered at the steelworks arise wherever energy is converted dynamically.”

Thomas Röseler, Head of Innovation and Projects at MR Power Quality

Since too much reactive power and harmonics overload the power grid and make it unstable, energy suppliers set limits that large industrial consumers are not allowed to exceed, with violations resulting in considerable costs. Companies such as SWT must therefore take measures to ensure that they do not feed too much of these disruptive factors into the grid. Until now, SWT has relied on an SVC (static var compensator) system with filter circuits and a thyristor-controlled reactor (TCR) to provide capacitive and inductive reactive power, and filter out harmonics. To remain prepared for the future, innovative solutions were considered to better meet upcoming requirements.

Efficient STATCOM system

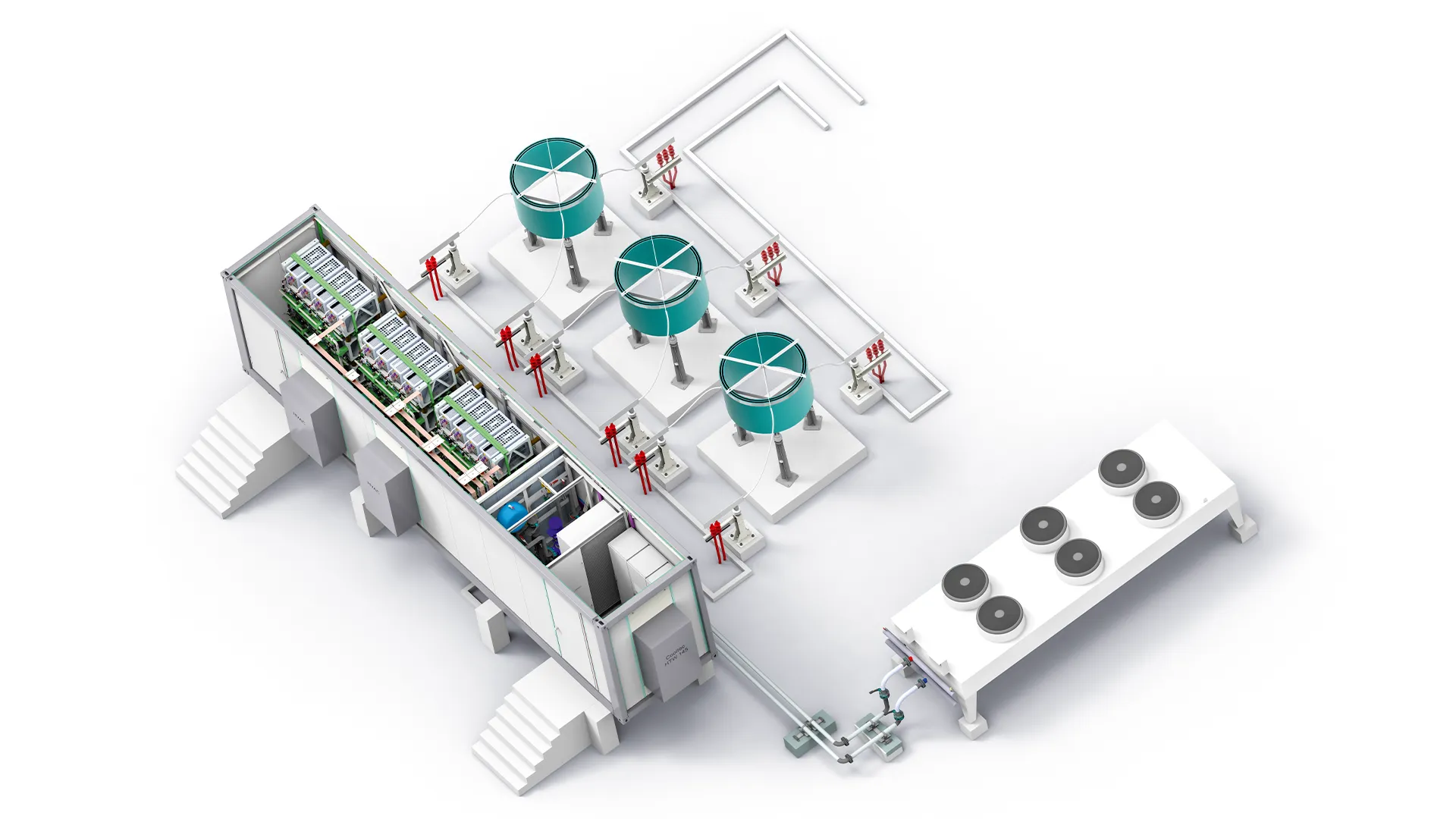

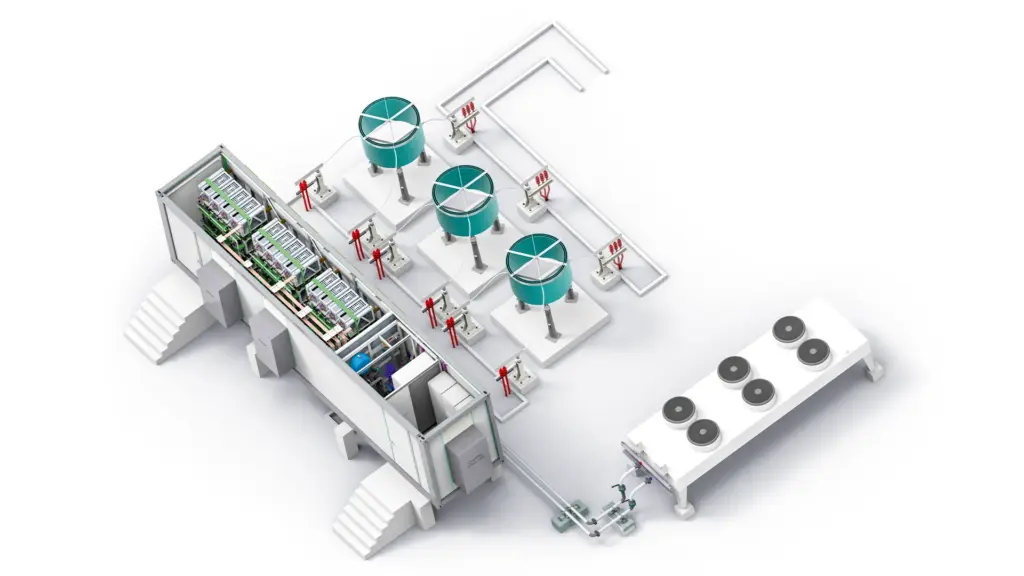

When colleagues from MR’s Power Quality Projects department presented a concept for a new STATCOM system at SWT, it came at just the right time. STATCOM (static synchronous compensator) is a system for dynamic reactive power control in electrical power transmission systems. It belongs to the FACTS (flexible AC transmission) family of systems or plants which were developed to improve the stability, efficiency, and flexibility of power grids. The main advantage of STATCOM systems is that they react much faster than an SVC plant and do not require filter circuits, which results in significantly fewer losses. Thomas Röseler, Head of Innovation and Projects at MR Power Quality: “We developed our GRIDCON® STATCOM MMC system specifically for industrial plants. This is because problems such as those encountered at the SWT steelworks arise wherever energy is dynamically converted.” SWT is the first customer to use this solution, with the new system scheduled to go into operation in mid-2026. Additional potential applications include electrolysis, mining, and traction power supply.

Even more areas of application

Steel mills are not alone in facing these problems—wherever electrical energy is dynamically converted, grid stabilization measures are necessary. The GRIDCON® STATCOM MMC system can also help in the following applications:

Mining

Mining

Many mines, such as those for copper mining, are located in remote regions with long transmission lines that are susceptible to voltage fluctuations. In addition, the large machines (conveyor systems, crushers, mills) require a lot of reactive power. STATCOM compensates for this.

Electrolysers

Electrolysers

Electrolyzers — for example, for hydrogen production — operate with powerful rectifiers and require large amounts of reactive power to function efficiently. Stable operation with optimal voltage reduces losses and increases the service life of the electrolysis cells.

Data centers

Data centers

In data centers, even the smallest voltage fluctuations can lead to data loss, hardware damage, or system failures. The IT infrastructure with servers and air conditioning systems also generates reactive power and other loads. STATCOMs counteract this.

The path to a STATCOM system

With the GRIDCON® STATCOM MMC system, MR Power Quality offers a standardized solution that can be implemented within a year with minimal planning effort:

1.

Planning:

A detailed initial discussion with the customer regarding prevailing conditions is followed by grid measurements.

2.

Design creation:

Following the grid analysis, the system is adapted to the customer’s requirements.

3.

Production of components and systems:

MR manufactures the MMC converters at its own plant in Regensburg. Other components are manufactured by selected suppliers in accordance with MR specifications.

4.

Installation and commissioning:

Installation is carried out by MR-authorized specialists and is supervised by the Power Quality team until commissioning.

5.

Service and maintenance:

Even after commissioning, MR provides support for system maintenance and ensures that spare parts are available.

The solution: perfectly compensated

Here you can learn more about how the GRIDCON® STATCOM MMC system is structured and how it works.