A groundbreaking invention is one thing. Translating it into consistently reliable production is another. A look at the production process shows how MR ensures the highest quality for every single VACUTAP® VV®.

Since its introduction 25 years ago, 35,000 VACUTAP® VV® units have left the factory in Regensburg on their way around the world. Each one consists of 1,920 individual parts and passes through a total of 15 work stations before being delivered as a finished on-load tap-changers. Whether during assembly of the individual components, final inspection, or shipping, the 24 employees involved in production ensure that every VACUTAP® VV® meets the highest quality standards and switches reliably for the entire life of the transformer.

How the VACUTAP® VV® is manufactured

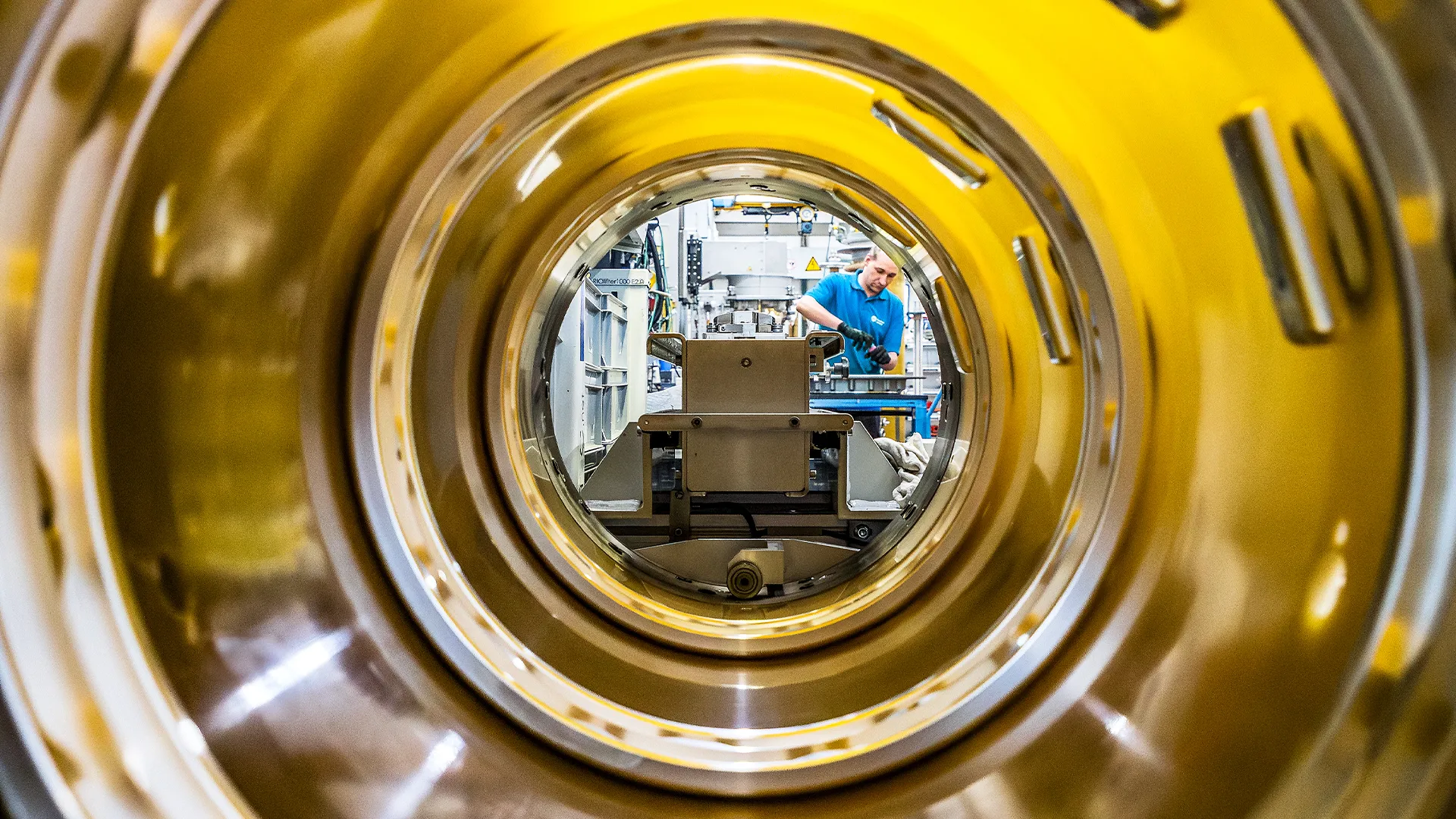

Manual work:

In this production step, an employee attaches the fixed contacts to the contact cylinder into which the selector switch with the vacuum interrupters will later be inserted.

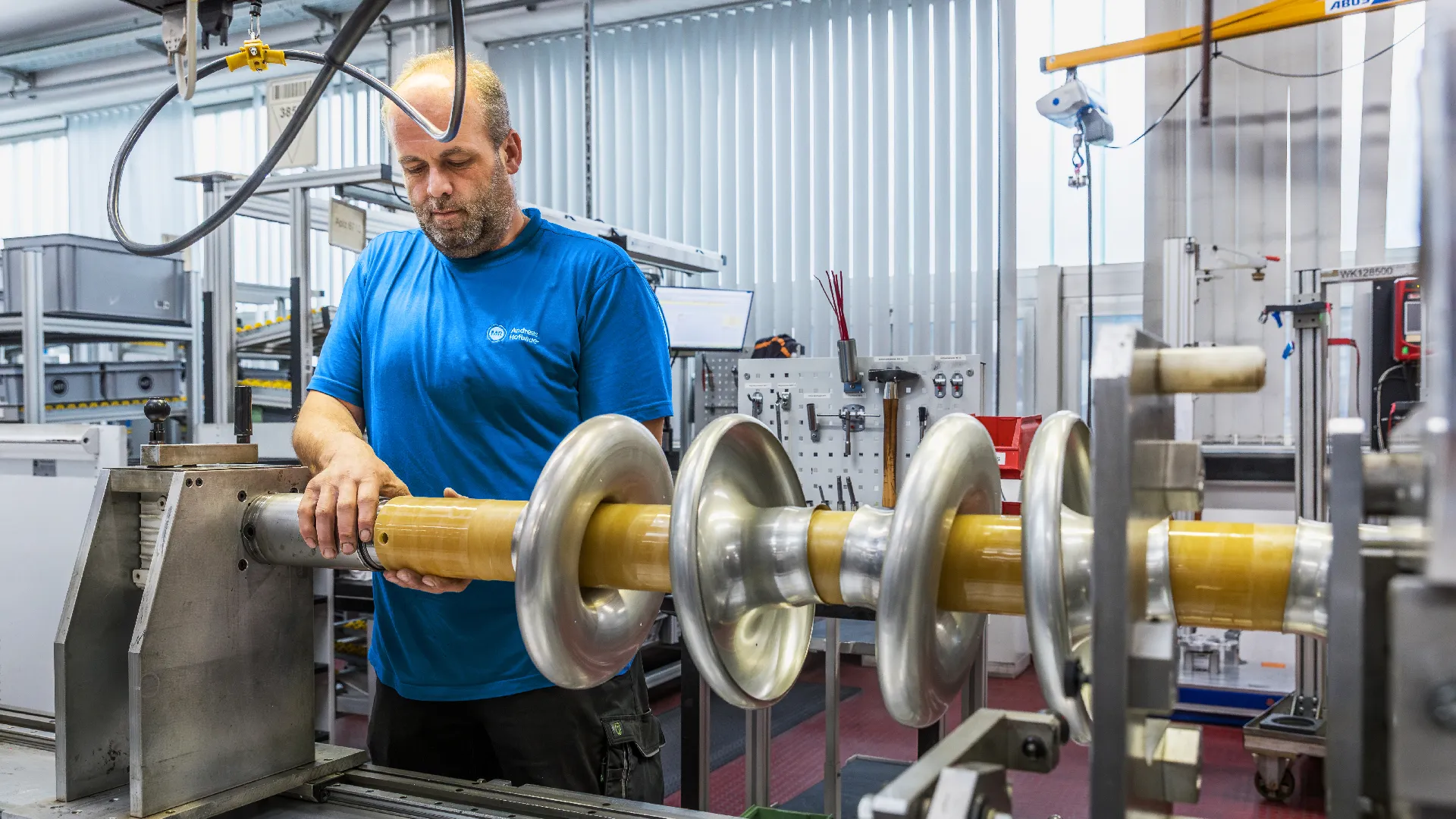

Drive-shaft assembly:

The drive shaft fulfills an important function in the on-load tap-changer as it converts the rotary motion of the drive motor into precise switching operations via gears, shafts and couplings.

Selector-switch assembly:

Here an employee prepares the selector switch for further assembly, such as the attachment of the switching segments with vacuum tubes.

Quality testing:

Once the contact cylinder, selector switch and drive shaft have been assembled, the VACTUAP® VV® is wired for measurement and put through its paces on the final test bench. Only if it passes all the tests will it be shipped.

Delivery preparation:

After a total of 15 production steps, the VACTUAP® VV® can be prepared for shipment. Somewhere in the world, it will then contribute to a stable and reliable power supply.