With the new VACUTAP® VI, MR is taking vacuum technology to a new level and making it even more efficient and sustainable. This innovative on-load tap-changer enables compact transformers for network operation that were previously unthinkable. A big step for a world that needs more and more energy.

Less is more

Less material, fewer components, less effort in transformer production – but maximum efficiency and more sustainability. With the VACUTAP® VI, the inventor of the on-load tap-changer is once again setting new standards.

Maximum compactness

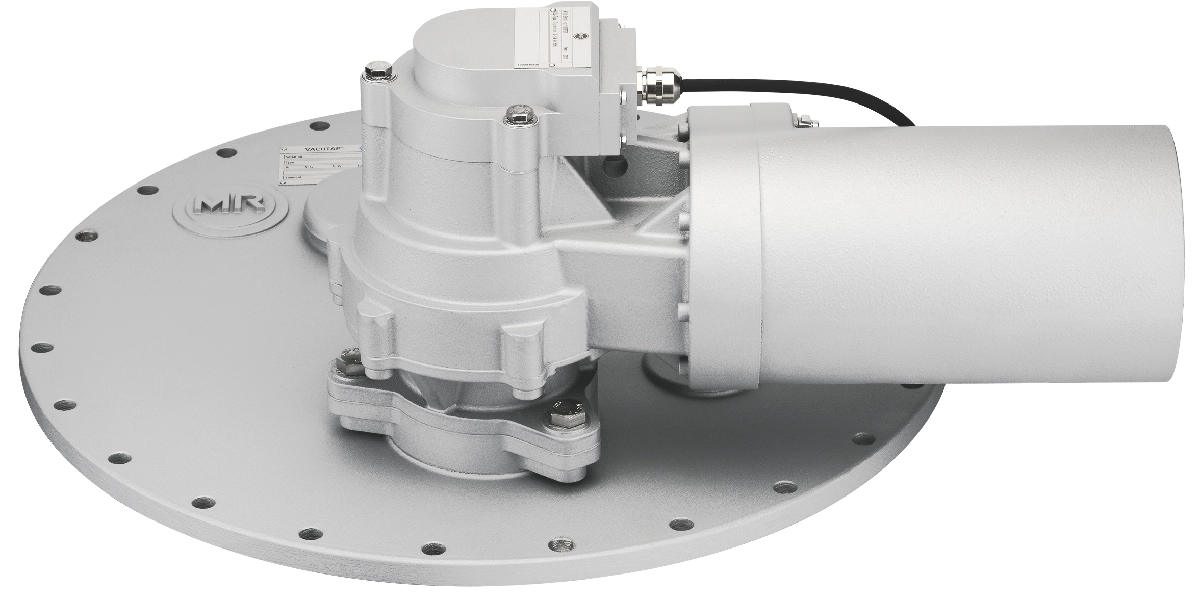

The VACUTAP® VI was developed for power transformers of up to 100 MVA. It shares the transformer’s oil system and therefore takes up significantly less space than conventional on-load tap-changers. All winding connections are located on one side, which simplifies the cable routing to the winding and also the installation.

Automatic drive control

MR offers two control cabinet solutions for drive control, which can be flexibly positioned directly on the transformer or externally. The TCC (Tap Changer Control) solution is the basic variant that controls the VACUTAP® VI effectively and reliably. The ETOS® ID offers additional comprehensive functions for monitoring and controlling the transformer.

Innovative direct drive

The innovative DC direct drive controls the tap-changer electronically without a spring energy accumulator, thus eliminating the drive linkage. An integrated power capacitor ensures continuation of the switching process even in the event of a power failure. An innovative control algorithm compensates for external influences such as high oil viscosity.

There’s a lot in it!

Efficient, sustainable and reliable – the most important advantages of the VACUTAP® VI at a glance.

Maximum efficiency

Maximum efficiency

With the new VACUTAP® VI, manufacturers can increase the output of transformers by up to 30 percent – while maintaining the same space requirement. Alternatively, transformers can also be built smaller while maintaining the same output. This is made possible by the compact dimensions of the tap-changer and a simplified winding connection, among other things. And since fewer additional components are required, transformer production also becomes significantly more efficient.

Environmentally friendly

Environmentally friendly

The VACUTAP® VI reduces CO² emissions by up to 25 percent over its entire life cycle compared to conventional vacuum tap-changers. It requires 135 kilograms less material and, thanks to its direct drive and shared oil supply with the transformer, components such as drive shafts and pipes can also be eliminated, which means less material use for transformer manufacturers. The MR engineers have also opted for high-performance plastics instead of energy-intensive aluminum.

Reliable

Reliable

The VACUTAP® VI incorporates the concentrated know-how that MR has gathered with vacuum technology over the last three decades. It was specially developed for network operation and is maintenance-free for up to 300,000 switching operations. It has been tested in the MR laboratory far beyond the standard requirements. Reliable arc quenching and a fail-safe switching concept ensure maximum operational safety.

New and already proven

With the VACUTAP® VI, MR is once again breaking new ground. And yet this innovative tap-changer concept already incorporates a great deal of experience that has been proven thousands of times in practice.

Entry into vacuum technology

MR entered the vacuum technology market 35 years ago. Since then, it has delivered over 120,000 vacuum on-load tap-changers to 150 countries worldwide.

First resistance tap-changer with vacuum technology

With the VACUTAP® VV®, MR was the first manufacturer to bring to series production vacuum switching technology for installation inside of oil-filled transformers. For the first time, this meant maintenance-free operation for almost all network applications.

Common oil system

The ECOTAP® VPD® for distribution transformers, which also shares the transformer’s oil system, is switching reliably in more than 10,000 applications in over 70 countries.

Intelligent drives

Since the introduction of the first intelligent head drive for power transformers, over 10,000 units are now in use in 150 countries.

Your contact persons

Do you have any questions about VACUTAP® VI? Then please contact us:

Leonie Kirschmer

L.Kirschmer@reinhausen.com

Marius Poschenrieder

M.Poschenrieder@reinhausen.com