With sensors and intelligent software, operators can make their equipment ready for the future.

The average age of transformer fleets worldwide is on the rise. Important expertise is being lost because skilled personnel are retiring. At the same time, increased electricity demand and the impact of renewables mean that the technical requirements placed on power grids are growing too. That’s why it’s more important than ever for operators to know exactly what condition their transformers are in—whether they need to run existing systems efficiently, repair installations, or prevent systemcritical conditions from occurring. The answer lies in intelligent transformers. In this regard, MR offers a range of individual digitalization modules as well as complete solutions.

Intelligence on all Levels

From the sensor to fleet monitoring — all automation levels incorporate Reinhausen’s accumulated expertise on transformers.

PROCESS LEVEL

SENSORS

Without data, analysis is not possible. The sensors on the transformer measure the parameters that are important for monitoring and control.

IT ALL STARTS AT THE SENSOR

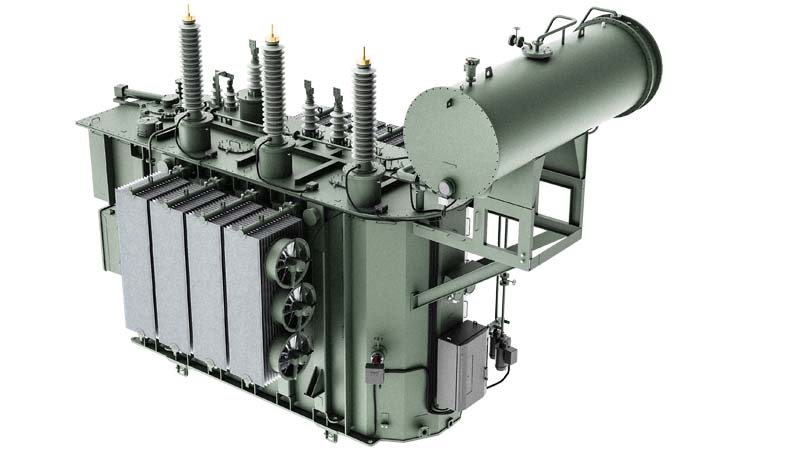

The sensors and protective devices on the transformer are constantly collecting data. Implementing an automation system involves tapping into these data sources and potentially integrating additional sensors. Under the brand names MESSKO and MSENSE, Reinhausen offers a wide range of measurement technology solutions. These include conventional sensors for temperature or fill-level monitoring, intelligent sensors for purposes such as bushing monitoring, as well as protective devices like the Buchholz relay. The system from MR is also open to the use of components from other manufacturers.

More information on sensor technology from MR: www.reinhausen.com/messko

FIELD LEVEL

MONITORING, CONTROL AND REGULATION

The hardware and software offered by MR analyzes the data collected at the transformer. Operators can choose from a range of different monitoring M and control C modules.

INTEGRATED SMART MODULES (ISM) — THE CENTRAL INTELLIGENCE UNIT

All of the data flows through fiber-optic cables into the central control unit, where it is analyzed and evaluated by algorithms (see page 30). The unit houses all the expertise on transformers that Reinhausen has built up over the decades. Three different designs are available: Operators can choose a finished control cabinet solution from MR, an integrated solution in an existing motor-drive unit, or integration in a separate control cabinet. Up to six different software modules are available for analysis to suit the needs of the application.

CONTROL LEVEL

FLEET MONITORING

From the grid control room, operators can use all the analyses that have taken place at the transformer to perform global monitoring of equipment.

ONE SYSTEM, MANY ADVANTAGES

- MAXIMUM OPERATIONAL RELIABILITYWith real-time monitoring of all equipment, operators can respond quickly when a fault is identified.

- EASY INTEGRATIONOperators can use both existing sensors and their own communications structure. This means that the data can be analyzed using the TESSA fleet monitoring system from MR as well as other systems.

- LOWER COSTSThanks to constant monitoring, operators can get a much more precise picture of the condition of their transformers without having to be on site. This enables them to not only reduce the number of maintenance intervals and inspections of the installation, but also quickly rectify any faults identified thanks to the advance warning system, avoiding the need for major repairs.

- SAFE SYSTEMThe automation solution from MR meets the high standards of safety required in energy technology.

- SIMPLE VISUALIZATIONThanks to the integrated web server in the central control unit, the condition of the transformer can in principle be monitored from any device, such as a smartphone, a tablet, or the screen in the control room.