The FLEETSCAN 2D assessment system allows network operators to keep an eye on their fleet at all times

All around the world, grid operators are being confronted with the same challenge: the fact that their equipment is reaching old age. It is no longer uncommon to see power transformers with a service life of 50 years or more. One of the questions that every grid operator is

faced with is therefore ‘What sort of shape is my fleet in?’ Finding an answer to this question is becoming more and more urgent: Fluctuating and higher loads resulting from renewable energy sources are increasingly causing the crucial pieces of equipment needed to ensure a stable power supply to reach their limits.

To combat this, Maschinenfabrik Reinhausen has developed a condition-based method to identify critical units at an early stage: FLEETSCAN 2D. The two dimensional assessment matrix incorporates, firstly, the likelihood of functions failing in order to model the reliability of the fleet. The second

dimension then considers the loss-of-life and is important for making long-term investment decisions. The manufacturer-independent evaluation tool is a lean solution on which operators can rely to keep their fleets in shape.

Fleetscan 2D

How is my transformer fleet doing? The fleet management solution from MR provides the answer in just a few steps.

1. Collect Data

A sufficient database is essential to carry out the condition assessment. To keep disruption times and assessment work to a minimum, FLEETSCAN 2D offers three assessment stages. Depending on how detailed the assessment needs to be, not all three stages have to be carried out. Transformer data is already available in many cases, so the work involved in recording the data is minimal.

1st stage: existing data

The operator provides the data which is already available. This includes, for example, the master data of the transformers, measurements that have already been carried out, and maintenance history information.

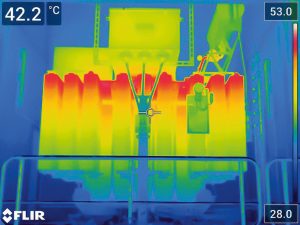

2nd stage: on-site appraisal

The second stage involves an on-site appraisal which is carried out during operation. In a visual inspection, an MR expert uses a checklist to examine the transformer for signs of corrosion, leaks, and visible damage to the bushings and fans. The expert then carries out infrared thermography and a complete oil analysis.

3rd stage: complete testing

If, after the first two stages, there are any indications of more significant damage, MR performs targeted testing involving extensive measurements. These include dynamic resistance and partial discharge measurements which require the transformer to be taken off the grid.

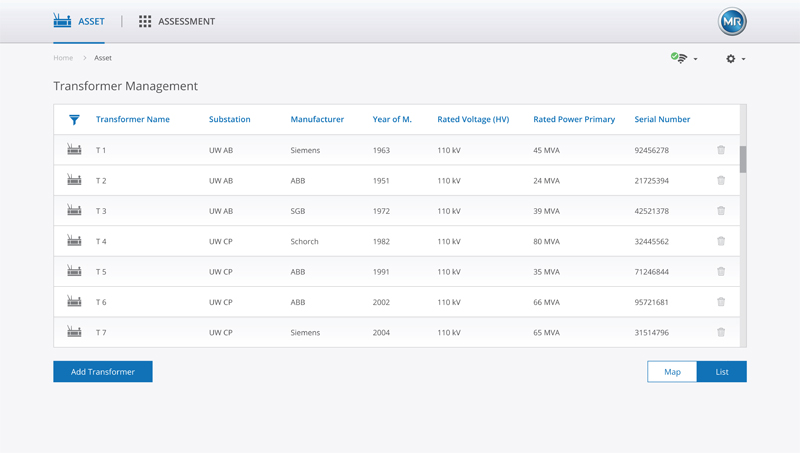

2. Everything at a Glance

FLEETSCAN 2D makes it possible to clearly save all collected data using browser-based software. This enables grid operators to retrieve

all relevant information for any transformer in the fleet at any time.

3. Evaluation

Following data recording, it is time to move on to the core element of FLEETSCAN 2D: the evaluation. Using an algorithm developed by MR and the University of Wuppertal, the condition analysis is carried out in two indices:

- The failure risk index measures the likelihood of functions failing. These values provide important reference points for the maintenance strategy, which is crucial for the OPEX budget.

- The loss-of-life index is a key variable when making long-term investment decisions, and is therefore relevant for the CAPEX budget.

For the assessment, the results of the two indices are transferred into an XY diagram. The condition of the fleet can thus be visualized simply: The more transformers that are located in the quadrants near the origin, the better the condition of the fleet and vice versa.

4. Recommendations

Once the assessment is complete, an MR expert will take a detailed look at the results, check the plausibility of the data, and offer recommendations. The grid operator will then receive a comprehensive report from which the measures that need to be taken, such as maintenance tasks and investment decisions, can be derived. Depending on the condition of the fleet, MR recommends that the FLEETSCAN 2D assessment be repeated every three to five years.

Your Contact

Would you like to use FLEETSCAN 2D to assess your fleet of transformers?

Alexei Babizki would be delighted to advise you:

A.Babizki@reinhausen.com