Sulphur hexafluoride is an excellent insulating gas for electrical applications but has a catastrophic greenhouse effect. An EU regulation is therefore gradually banning its use. HIGHVOLT is prepared for this and is making its gas-insulated test and measurement systems future-proof.

Would you like to know how HIGHVOLT mastered the challenge? Then simply slide the switch to the right!

Task

Result

Challenge

Sulphur hexafluoride (SF6) is an ideal insulating gas for gas-insulated switchgear (GIS) systems, which control the flow of energy in substations or industrial plants, switch off circuits when required and protect the high-voltage grid from overloads. Compared to outdoor switchgear, GIS systems take up significantly less space and are therefore particularly suitable for use in urban areas. And thanks to the outstanding properties of SF6, very compact designs are possible. However, this popular insulating gas has a serious disadvantage: a catastrophic climate footprint. It is around 23,500 times more harmful to the climate than CO² and remains in the atmosphere for 3,200 years.

3,200

years

SF6 remains in the atmosphere.

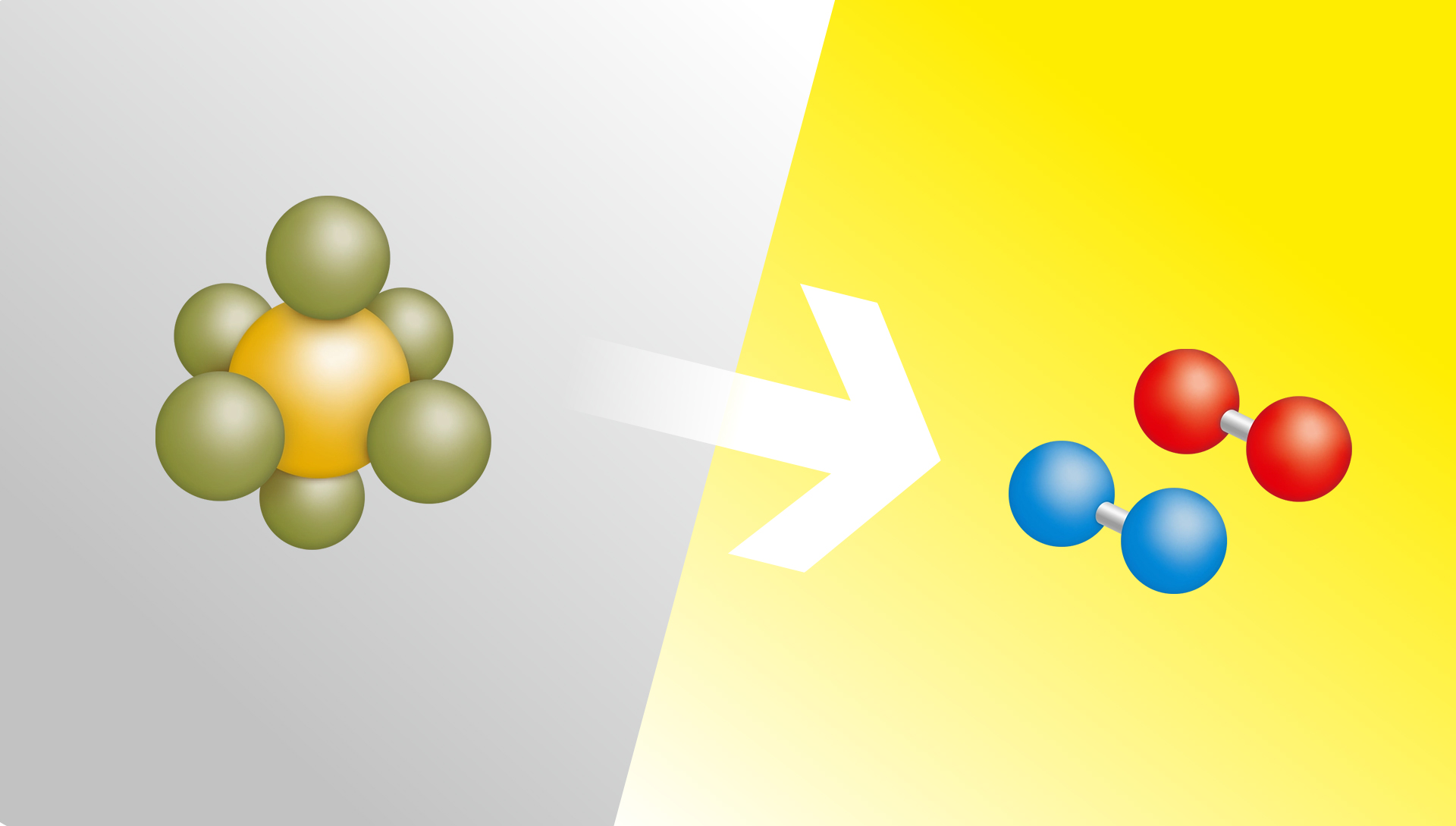

Sulphur hexafluoride (SF6)

is the perfect insulating gas for electrical applications thanks to its excellent insulating properties.

23,500

more

more harmful to the climate than CO2

In 2024, a new F‑gas regulation therefore came into force in the EU, which increasingly restricts the use of fluorinated gases and completely bans SF6 gas in new electrical installations starting from 2032. This also affects HIGHVOLT’s gas-insulated testing and measuring systems, which manufacturers and operators need to test GIS systems. Dr. Tobias Gabler from HIGHVOLT explains: “The challenge is that there is no other gas that has similarly good properties to SF6.” Although there are already alternatives on the market that have a significantly better carbon footprint, some of them also contain fluorinated gases, which the EU also wants to ban. “We wanted a future-proof solution for our systems. We want our customers to be able to rely on the assurance that they will still be able to use their testing systems in ten years’ time,” explains Gabler.

Solution

So, what is the alternative? The answer sounds very simple: synthetic air. It consists of nitrogen and oxygen, has a global warming potential of zero and is therefore completely harmless to the climate. The catch: synthetic air has significantly poorer insulating properties and cannot replace SF6 gas on a one-to-one basis. “However, the disadvantages can be overcome if we revise the design of our testing and measuring systems,” explains Gabler. The testing experts at HIGHVOLT are therefore gradually scrutinizing all measuring and testing systems and investigating how they can adapt the components to the new requirements. For example, the insulating capacity of synthetic air can be significantly improved by almost doubling the operating pressure in the systems from four to seven bar. This in turn requires thicker walls for the vessels so that they can withstand the higher pressure.

Future-proof

Synthetic air carries no risks which means that it can be used permanently regardless of future regulations.

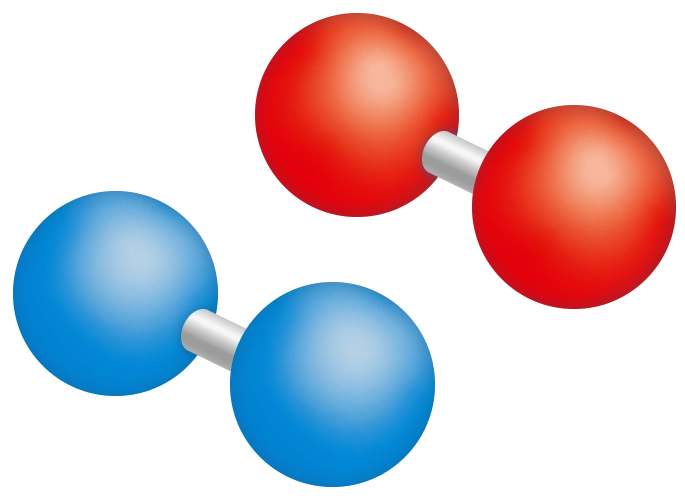

Synthetic air

consists of nitrogen and oxygen.

0 Global warming potential

Synthetic air carries no risks which means that it can be used permanently regardless of future regulations.

“We also have to increase the insulation distances and adapt the electrode geometries. Overall, these measures make our systems around 20 percent larger, but otherwise all functionalities remain the same,” says Gabler. As more and more GIS manufacturers are also increasingly relying on synthetic air, HIGHVOLT’s systems are compatible with them. However, existing systems that are still operated with SF6 can also continue to be tested if appropriate adapters are used. “Our systems are very flexible in this respect,” emphasizes Gabler.

In addition to the environmental aspect, synthetic air also has other advantages for operators such as much easier gas handling. As Gabler explains: “Maintenance is much more complex with SF6 because the gas has to be extracted at great expense and a number of safety precautions are also necessary, for example during transport – all of this is eliminated or simplified with synthetic air.” The requirements for synthetic air are also less strict, and synthetic air is more readily available and significantly cheaper than SF6.

The HIGHVOLT engineers have already adapted the first resonant reactor coil for its AC voltage test systems to the new insulating medium. “This means we are currently one of the first manufacturers to bring testing technology with synthetic air onto the market.” Further testing and measuring systems will gradually follow so that all HIGHVOLT product series will be able to operate with synthetic air from 2028 onwards. .

Reinhausen Inside

The following systems from HIGHVOLT have already been adapted or will soon be available with synthetic air:

2025

- AC voltage resonance test system WRVG / resonant reactor coil for 340 kV test voltage

- LiMOS power loss measuring system for 100 kV test voltage

- MCP standard capacitor

From 2026

- LiMOS power loss measuring system for 200 kV test voltage

- WRVG AC voltage test system for test voltages up to 680 kV

Your contact person

Do you have any questions about gas-insulated test and measurement systems? Dr. Tobias Gabler is here for you:

T.Gabler@highvolt.com