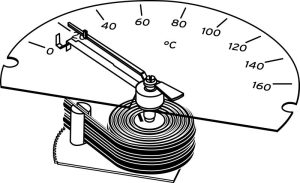

The pointing thermometers from MESSKO, a subsidiary of Reinhausen, would simply not work without Bourdon tubes. The thermometers are used for monitoring the temperature of transformers and have to withstand extreme conditions in terms of heat and moisture. The Bourdon tube is a flattened, normally coiled metal tube, and is one of the three main components of the thermometer together with the temperature sensor and the capillary tube.

The tube is named after the French engineer Eugéne Bourdon, who patented the measurement principle in 1848. It works as follows: A temperature sensor is filled with a fluid which expands as the temperature rises. This raises the pressure in the coiled Bourdon tube which is connected to the sensor in a closed system, causing the tube to bend upwards.  As the temperature falls, so too does the pressure and the coil bends back into place. These movements are transferred to a pointer needle which is fixed to the end of the tube and points to the corresponding degree value on a calibrated scale. The Bourdon tube is therefore a crucial component for the precision of the measurement and the service life of the thermometer. For this reason, MESSKO manufactures this component itself from a special, thermally treated copper alloy. A maintenance example from Argentina is perfect for outlining how robust these thermometers are: After 45 years of continuous service, three thermometers were still doing their jobs reliably. All that was needed was a bit of cleaning.

As the temperature falls, so too does the pressure and the coil bends back into place. These movements are transferred to a pointer needle which is fixed to the end of the tube and points to the corresponding degree value on a calibrated scale. The Bourdon tube is therefore a crucial component for the precision of the measurement and the service life of the thermometer. For this reason, MESSKO manufactures this component itself from a special, thermally treated copper alloy. A maintenance example from Argentina is perfect for outlining how robust these thermometers are: After 45 years of continuous service, three thermometers were still doing their jobs reliably. All that was needed was a bit of cleaning.

MESSKO started using Bourdon tubes for the first time in 1932. Since then, the measurement experts have consistently worked to optimize this essential component.