Unplanned outages of long underground cable routes cause a lot of effort and high costs for network operators. HIGHVOLT now offers an early warning system.

Unplanned outages of long underground cable routes result in a great deal of effort and high costs for network operators. How nice it would be to have a system that closely monitors the cable routes and provides recommendations for action to reduce these costs. HIGHVOLT has a solution for this that can also be retrofitted.

The energy transition can only succeed with higher transmission capacities. But communities and residents often oppose the erection of high-voltage pylons in their neighborhoods, and petitions, political conflicts and long lawsuits are often the result. To avoid this hassle, network operators like to use kilometer-long underground cables, but then get themselves into other trouble because laying, repairing and replacing these cables is many times more expensive than with overhead lines. A monitoring system for detecting cable faults and evaluating partial discharges would significantly reduce the cost of repairs, cut possible downtimes and allow network operators to sleep more soundly again.

160 km under control

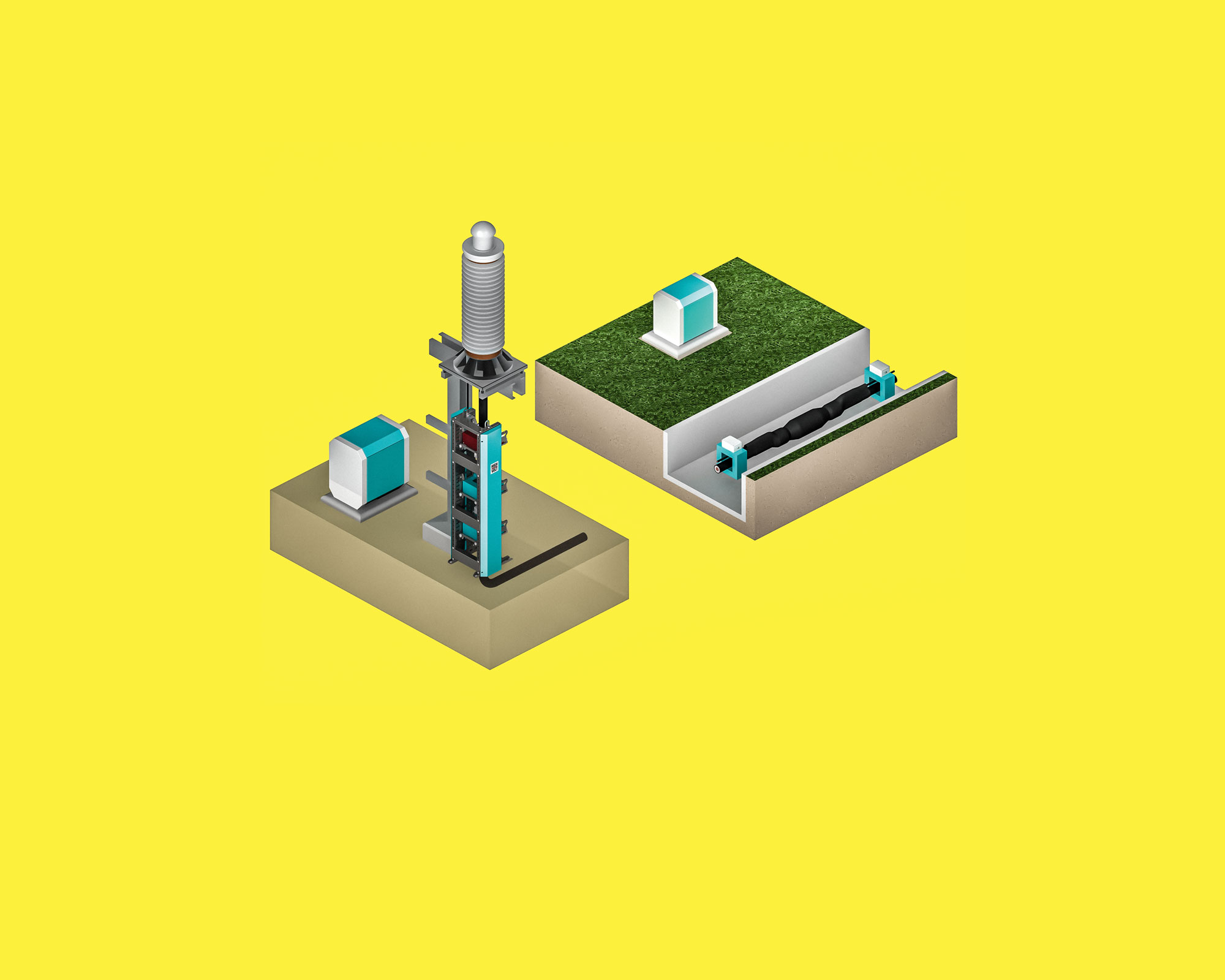

Fortunately, there is now such a monitoring system—HiMON® from HIGHVOLT—which uses two types of sensors to record measured values: the HiMAG® Red and HiMAG® Blue high-frequency current transformers. Matthias Kappler, HiMON® project manager, explains: “HiMAG® Red is responsible for detecting the traveling waves—also known as transients — caused by cable breakdowns in order to determine the point of origin.” For this purpose, a HiMAG® Red sensor with an associated HiRES® Locator event recorder is placed at the beginning and end of each cable section. HiMAG® Blue, on the other hand, is installed along the cable route at the grounding sleeves at distances of up to twelve kilometers. “The HiMAG® Blue sensors detect microscopic pulses that occur at possible fault locations in the cable insulation,” adds Dan Keller, Utility Business Sales Manager at HIGHVOLT.

“The system can record very precisely where and in what intensity partial discharges occur. From this, clear recommendations for action can be derived.” Dan Keller, Sales Manager Utility Business at HIGHVOLT

Detecting partial discharges in long underground cable runs is very costly using traditional means. “The disadvantage of systems based on the traditionally prevailing partial discharge (PD) measurement methodology is that they require a sensor at each joint,” says Keller. In the past, the high associated installation costs often led cable operators to choose to use only acoustic-signal-sensing or temperature-sensing systems using fiber optic cables. However, this leaves certain damage to the cable insulation undetected.

HiMON® optimally supplements the fiber-optic-based systems already in use with a system for detecting electrical partial discharge signals. The TruePD methodology developed for this purpose significantly reduces installation efforts because the measuring points are only installed at the grounding sleeves at distances of up to twelve kilometers. HiMON® thus saves a lot of material and money. In addition, for the first time, HiMON® also allows the cable sections between the measuring points to be monitored with centimeter-exact accuracy. Alternative PD measuring systems can usually only monitor the joints.

Easy to install

The HiMON® monitoring system is also easier to install and retrofit due to the low number of measuring points and the newly developed design. Matthias Kappler explains, “Unlike conventional systems, the HiMAG® sensors can also be retrofitted to already installed cable systems thanks to their separable core design.”

Action recommendations

Part of the energy transition is also the digitization of existing infrastructures to improve condition monitoring and maintenance. The measurement signals captured by the HiMON® sensors are digitized by the associated HiRES® TruePD event recorder and this data is then sent to a specially secured cloud where it is analyzed by intelligent algorithms. “The cable network operator then receives information about the condition of the cable route including visual information in the form of traffic lights,” says Kappler. If the traffic light turns red, HiMON® shows further details about the problem such as which cable component is affected, or the intensity of the partial discharges. “The system can record very precisely where and in what intensity partial discharges occur, from which clear recommendations for action can be derived,” Keller explains. This is important information for cable network operators in order to repair possible defects during planned cable maintenance. This is easy on the wallet and ensures secure networks.

YOUR CONTACT

Do you have any questions about the project?

Dan Keller is there for you:

d.keller@highvolt.com