Harmonics damage electrical devices, but most filter solutions are too complex for users to understand. Holger Kretzschmar from Reinhausen Power Quality has the answer: the Total Harmonic Solution modular system.

Total Harmonic Solution—it certainly sounds like a system that can solve any problem. What does it involve exactly?

That’s precisely what we want to achieve with the Total Harmonic Solution. It is a modular system comprising passive and active filter solutions which can be used

to eliminate all kinds of unwanted harmonics in low-voltage and medium-voltage networks. Including those that are set to increase in the future.

Why was this development necessary? What can we expect to see in the future?

Networks have changed. Back when the world was simple, all we had to do to keep the voltage stable was compensate for reactive power. Things started to change in the 2000s: More and more frequency-controlled drives are now used in machines. These are very energy-efficient, but the power electronics have a negative impact on the network which can cripple entire production lines.

„Small power electronics break quickly when subjected to higher vibrations, which can be expensive when a whole hall is lit with LED lamps.“

To begin with, it was mainly the fifth harmonic that caused problems—which could initially be rectified with passive filters. But as the number of frequency-controlled drives grew, additional harmonics emerged: We now had to deal with the seventh, eleventh, right up to the 51st harmonic. This is done with active filters. And now we have a situation where supraharmonics — vibrations in higher frequency ranges of two to nine kilohertz — are causing problems.

One Solution For Everyone

Clean voltage is crucial to ensuring reliable operation in numerous applications. Unwanted grid feedback effects can disrupt operation, resulting in additional costs and even total failure. With the Total Harmonic Solution modular system, this kind of disruption can be prevented without any need for complicated planning work. The four examples below demonstrate how the Power Quality filter solution can be used to ensure stable voltage.

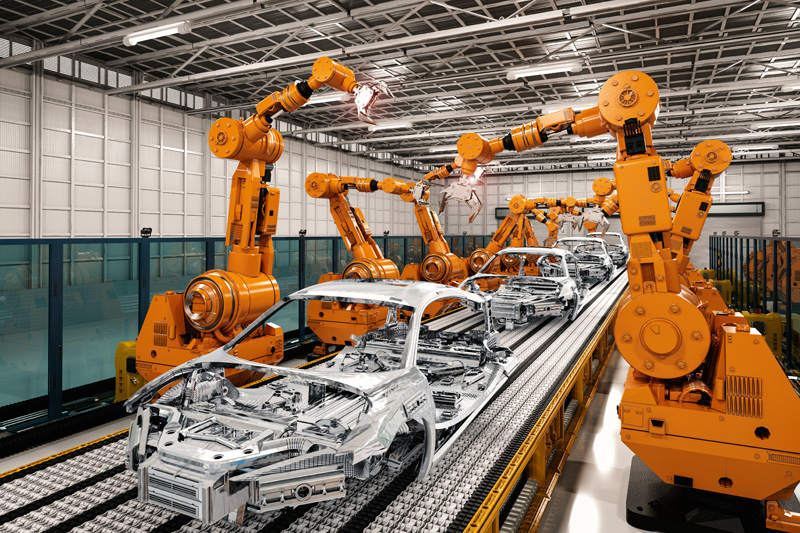

Example 1: The automotive industry

The automotive industry is a classic field of application for filter solutions. In this sector, power electronics enable reliable, highly automated production on a massive scale. This goes hand in hand with a considerable risk of disruption — but, fortunately, this risk can be easily minimized with the right filter solutions.

Example 2: The water industry

The water industry is keen to maximize its energy efficiency. To this end, power generation plants (such as solar power plants) are increasingly being integrated into modern treatment facilities, complete with frequency converters, in order to operate electrical pumps — which are themselves increasingly being equipped with frequency converters as well. Disruptive harmonics are therefore inevitable.

Example 3: Wind power

When electricity is being generated from wind power, harmonic currents often occur, disrupting the power quality within the grid. If plants frequently exceed the prescribed limit values in this regard, they have to be removed from the grid. In the worst cases, they may even lose their operating licence.

Example 4: Ships

Ships are fitted with complex electronics. Frequency-controlled drives for compressors, bow and stern thrusters, main drives with several megawatts of power, as well as power inverters for shore power supply are just some of the technical innovations being put to use in the shipping sector. As a result, the on-board power supply can quickly become overloaded by harmonics.

This is due to the use of active front ends (AFEs)—a type of frequency converter—which are set to become much more widespread in the future. In the past, supraharmonics didn’t cause anyone any prob lems—a punching machine is robust enough to withstand them—but modern loads are becoming more and more sensitive, as shown by the example of LED lights. Small power electronics break quickly when subjected to higher vibrations, which can be expensive when a whole hall is lit with LED lamps. We therefore realized that we needed to find a way to solve these problems once and for all.

What was your solution?

The system is very much based on tried-and-tested technology. The GRIDCON® CHF passive filter eliminates the fifth harmonic. For some applications, this module will be enough. More extensive protection is offered by the GRIDCON® ACF active filter, which covers the range up to the 51st harmonic. And for supraharmonics, there is our newly developed SHU filter module. Thanks to the modular structure, customers can select precisely what they need, and retrofits are also possible.

“Thanks to the Total Harmonic Solution, problems with harmonics will be a thing of the past.”

But what makes the Total Harmonic Solution really special is the device software that we have spent years honing and optimizing. The software measures the harmonics and the algorithm continuously analyzes the interference level and automatically counteracts it to ensure that the defined limit values are not exceeded. When it came to the programming, we made sure that we incorporated all of the experience our service technicians have had in the field. We can’t simply do things “by the book” if we want to reflect reality.

.

Filter solutions have a reputation for being very complicated …

That’s true. There are numerous individual solutions in use in the field which are highly complex and oversized. Parameterization can also be extremely laborious during commissioning or in the event of network modifications. With our standardized approach, it’s a different story. We wanted a solution that—to put it bluntly—was as simple, reliable, and durable as a lightning arrester and which could be installed based on the plug-and-play principle, wherever it is needed or wherever there is enough space.

Depending on the situation, sometimes all that is required is a compact wall device. With our modular system, that can be easily arranged. Current transformers are not required and parallel operation with other filters is also possible—it doesn’t get more flexible than that. The system regulates itself automatically and filters exactly what needs to be filtered. And if a company modifies its production line and the network changes as a result, that’s no problem either—the new parameterization takes care of itself with no need for a visit from a service technician.

What applications is the solution suitable for?

It is aimed at anyone who has problems with harmonics. This applies to virtually all highly automated production facilities, such as those in the automotive industry. But our filter solutions are also in demand at sewage works, at wind and solar farms, and even for on-board power supplies on ships.

REINHAUSEN INSIDE

The Total Harmonic Solution system comprises three freely combinable components:

The Total Harmonic Solution system comprises three freely combinable components:

- GRIDCON® CHF for the fifth harmonic

- GRIDCON® ACF for the third to 51st harmonic

- SHU filter modules for supraharmonics in the higher frequency range up to 10 kHz

The software is programmed such that the control system adapts automatically and with high precision to the respective network and its specific vibration behavior. Installation is incredibly easy and makes use of the plug-and-play principle — there is no complicated parameterization involved.

YOUR CONTACT

If you have any questions about the Total Harmonic Solution,

Holger Kretzschmar will be happy to advise you:

H.Kretzschmar@reinhausen.com