The TESSA® APM (asset performance management) software shows the status of transformers in real time. With installed intelligence, it extends the service life of the assets and enables more efficient maintenance.

Regular offline assessments and online monitoring can reduce the likelihood of a transformer failure by 70 percent. Studies from CIGRÉ and IEEE have demonstrated this. This is nice to know. But the reality often looks like this: By the time a transformer reaches the critical years when it needs more attention, it has been in service for a good 25 or 30 years. The commissioning was half a working lifetime ago by then. Experts take knowledge of the important grid resource with them into retirement, and data is often scattered or incomplete. Budgets shrink, while the demands of growing energy needs and the volatility of renewable energies increase.

To leverage this potential for fleet operators, Reinhausen has developed TESSA® APM, a solution for asset performance management. It combines on-site inspections and sampling through field devices with online monitoring. Consistent data management and the digitalization of many individual processes in asset management create a solid database. The result is full transparency on the condition of assets at all times, from the fleet level down to individual components.

INTELLIGENT MONITORING

However, the developers of TESSA® at Reinhausen said to themselves: 70 percent lower probability of failure? We can do better! Because there are two things still missing from the equation: Reinhausen’s many years of experience with transformers and the ability to apply that experience to the data via algorithms and artificial intelligence.

The results are status analyses, forecasts, and clear recommendations for action for systematic predictive maintenance of fleets. This further reduces the likelihood of critical failures, helps decide when and where to invest, and significantly extends asset life. And if the operating and maintenance data and history of the transformers are not available from the start of commissioning, Reinhausen offers the right solution for an up-to-date status assessment with FLEETSCAN 2D. This means that TESSA® APM can also be used for older transformers that are already in operation.

From the past:

TESSA Asset Performance Management itself has a key asset: Reinhausen’s decades of knowledge and experience with transformers. This affects both the programming and the training of algorithms and AI for data analysis as well as the forecast for efficient maintenance. In addition, this experience is incorporated into the practical design of the software with its intuitive dashboard and the visual presentation of the data.

Into the present:

TESSA connects the offline and online worlds to consistently map the exact status of each asset down to the modules at all times.

Offline: On-site inspections by operators’ internal specialists or external service providers such as Reinhausen itself regularly provide fresh field data. In addition, there is data from field samples that are analyzed in the laboratory.

Online: TESSA takes sensor data from digitalized transformers and adds it to the overall picture. This means that any fault is detected immediately.

For the future:

The algorithms and artificial intelligence programmed and trained by Reinhausen constantly look to the future. They recognize patterns in the data that indicate future defects or impairments. They also categorize and prioritize the findings and provide clear recommendations for action.

In this way, the software helps to optimize maintenance intervals and thus save costs. In doing so, it relies not only on current data but also includes past data in order to better assess the resilience and development of an asset over its service life and to be able to make more reliable forecasts.

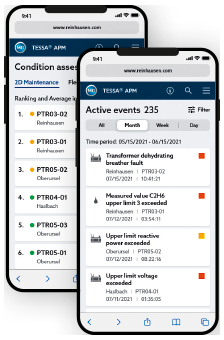

Always fitting

TESSA is browser-based and adapts with full responsiveness to the end device and application. On a PC, the focus is on the generous dashboard. On a cell phone, the most important data is bundled for a quick overview. For on-site work at the transformer, initial data evaluations come to the foreground.

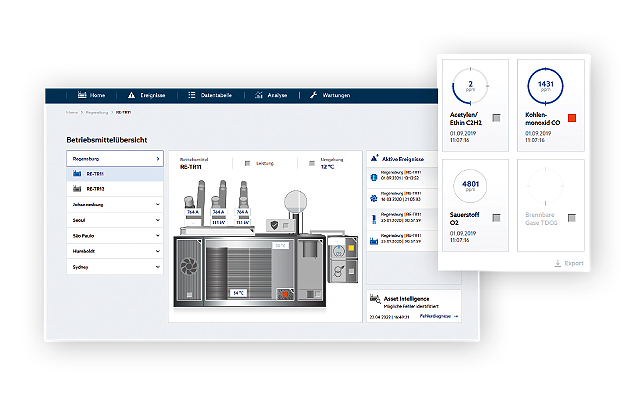

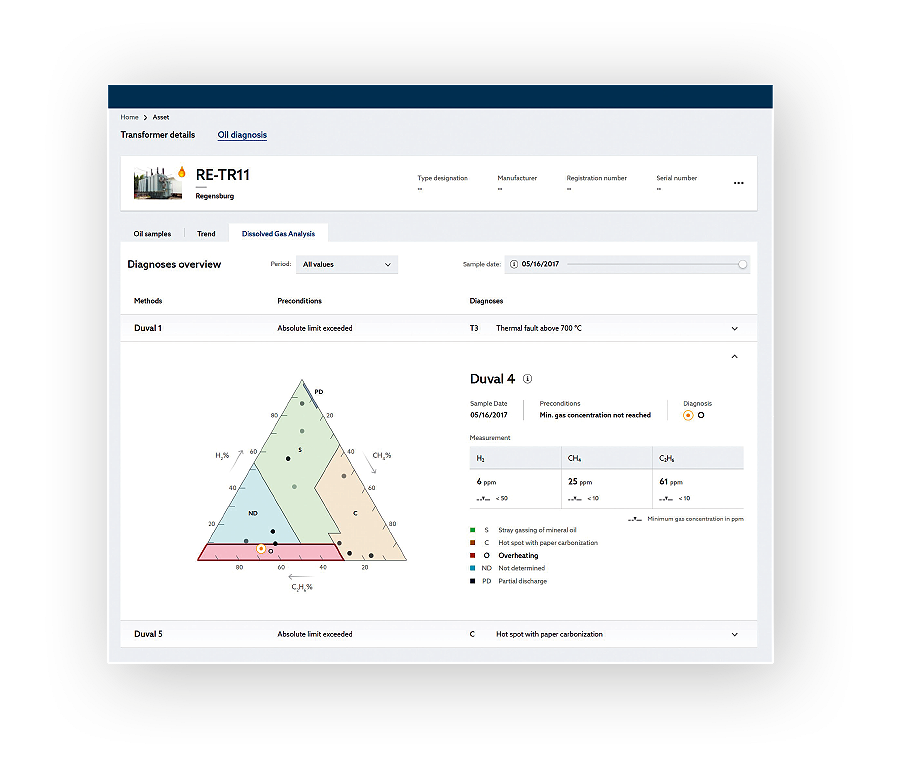

Structured

The dashboard shows asset managers the status of the fleet, upcoming deadlines, and event lists with current and prioritized incidents. Fleet monitoring takes us to the detailed level with analyses, individual data, and recommendations for action plus explanations about them: For example, the analyses of the laboratory results of the oil sample investigation, for which further diagrams and recommendations are offered.

Compatible with all manufacturers

TESSA is open for all. The system receives and stores data from sensors and components from all manufacturers.

Predictive

TESSA uses all available offline and online data to find potential faults, estimate failure probabilities, and provide analyses and action options for the solution. The software is also ready for the use of ISO 55000 and its data protection is optimized on an ongoing basis.

By the way: FLEETSCAN 2D is the optimal tool to integrate an up-to-date condition assessment of existing transformers into TESSA.

Read more: www.reinhausen.com/tessa-apm

“Experience meets data meets digitalization.”

Thorsten Krüger

Your contact

Do you have questions on TESSA® APM?

Thorsten Krüger is there for you:

T.Krueger@reinhausen.com