Reinhausen Power Composites unites its expertise in post insulators under the brand name RECOTEC® POST INSULATORS.

There are numerous components in primary substations and converter substations – such as smoothing reactors, thyristors or rectifier towers – that have to be insulated from the ground potential. They sit on a throne of special post insulators many meters off the ground. Not only do these posts have to bear the weight of components, which weigh tons, they also have to be capable of withstanding torsional and bending forces at the same time.

DDepending on where the applications are located, they can be shaken by earthquakes or strong winds. There are also increasingly higher voltage ranges that have become necessary due to the energy transformation in order to transfer electricity across long distances with as little dissipation as possible. Post insulators therefore need to be capable of insulating up to 1,100 kilovolts against ground. For many years, Reinhausen Power Composites has been an expert in composite hollow insulators and specializes in exactly these types of extreme applications.

Strong pipes, flexible shielding

Pipes made of fiber-glass-reinforced plastic are crucial for stability. Starting at the design stage, every detail matters. The angle and layer design, as well as the type of fiber-glass winding, determine the mechanical and electrical properties. Specialists at Reinhausen Power Composites develop the design using the finite element method (FEM) which allows them to manufacture the pipes to the respective customer’s precise requirements.

The higher the voltage, the longer the creepage distance. This can be controlled, on the one hand, by the length of the composite insulators. RPC is capable of producing up to 12.5 meters in a single piece. The second important component is the shielding: the creepage distance is lengthened using special shield profiles, especially for DC applications.

For HVDC applications, for example, components such as shield profiles with special dripping edges are required. Power Composites uses a variety of shielding technologies. For example, extrusion technology has high flexibility with respect to its geometry, ensuring that it can be highly customized to meet the customer’s wishes.

Filling and monitoring

Post insulators are typically filled with gas to prevent any moisture from getting inside them. In order to meet all customer requirements, RPC has also developed an insulating foam which make the post insulators – in contrast to the gas-filled variant – not only maintenance-free, but also environmentally friendly since they do not emit any insulating gases that are harmful to the environment.

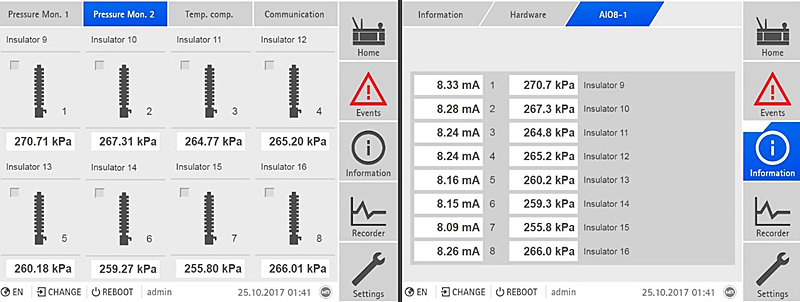

On request, solutions for monitoring the pressure and temperature of the gas can also be developed. Sensors from our subsidiary, MESSKO, offer solutions that have been proven in the field time and again.

All benefits at a glance

- Voltage ranges up to 1,100 kilovolts are possible

- Post insulators can be filled with either gas or foam

- Pressure and temperature monitoring with MESSKO sensors

- Pipe lengths of up to 12.5 meters in one piece

- Flexibility in terms of shield profile selection

YOUR CONTACT

Do you have any questions about the insulators?

Contact Manuel Surnic:

M.Surnic@reinhausen.com