Distribution grids are a key element on the path to a fully electrified world. To prepare them for the challenges of tomorrow, large-scale use of voltage regulated distribution transformers (VRDTs) is the most efficient solution. The third generation of the ECOTAP® VPD® enables voltage regulation to become standard in distribution transformers.

Why VRDTs are becoming ever more important

1 DECENTRALIZED GENERATION

is increasing, and with it the need to increase the performance of distribution grids.

2 ADDITIONAL LOADS

Mobility and heat will be electric in the future. The hosting capacity for these additional loads must increase.

3 DUAL ROLE

With solar systems on roofs, more and more consumers are also becoming producers. Distribution grids have to dynamically respond to these dynamics.

4 MORE FLEXIBILITY

in sector coupling can be utilized more efficiently of distribution grids have greater capacity.

5 THE COMPLEXITY OF GRIDS IS INCREASING

and the digitalization of distribution grids helps master this issue.

Simply powerful

The third generation of ECOTAP® VPD® makes voltage regulation the standard in distribution transformers.

500,000 SWITCHING

is what ECOTAP® VPD® is capable of. This exceeds the average service life time of a typical local grid transformer.

Smartly into the future

Thanks to ECOTAP® VPD®, digital connection is no problem and the VRDT becomes active equipment in the digital distribution grid.

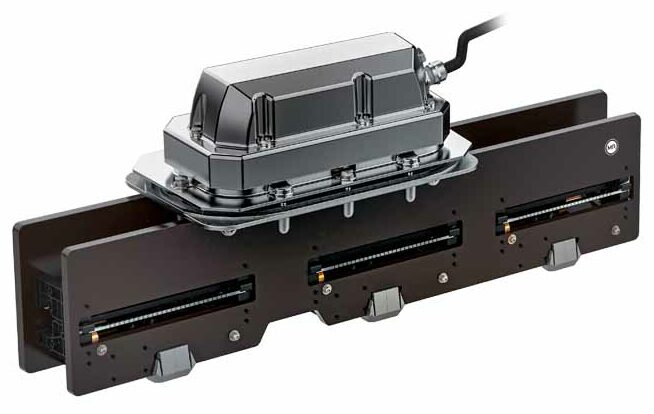

Very compact

The volume of the new ECOTAP® VPD® has been reduced by 50 percent in comparison to its predecessor.

30 %

less weight is what the new ECOTAP® VPD® including motor-drive unit brings.

Maintenance-free operation

Vacuum tap-change technology ensures a long service life and virtually no maintenance effort.

Automated production

The new ECOTAP® VPD® was designed for automated production in high quantities. As a result, costs can be reduced significantly and voltage regulation can become the standard in distribution grids. Production takes place in a newly constructed plant in Italy.

How does a VRDT work?

New power suppliers, such as photovoltaic systems on roofs, lead to voltage increases in local networks. New loads, such as those caused by e‑mobility, lead to additional voltage drops. Distribution grids to date have not been designed for this. Since medium-voltage and low-voltage grids are rigidly coupled via distribution transformers, the most common option used in the past, was to expand the grid. That is expensive! Depending on grid conditions, the hosting capacity for additional loads and suppliers can be increased two to four times using a VRDT, without needing to reinforce the cable network. How does this work? The control and regulating unit 1 continuously measures the secondary voltage 2 uand automatically outputs a signal to the tap changer when it needs to change the transformer ratio 3. The control and regulating unit can also be connected with SCADA systems 4 to support more sophisticated voltage control schemes.

Where does the ECOTAP® VPD® fit in?

In addition to distribution grids, VRDTs are also suitable for industrial applications and renewable production systems.

Distribution grid

Distribution grid

The distribution grid is the main application for the new ECOTAP® VPD® with 30 amperes.It keeps the voltage in the low voltage grid stable and is designed for transformers up to a voltage class of 24 kV.

Industry

Industry

If very precise voltage or a larger regulating range is needed, ECOTAP® VPD® with 100 amperes and change-over selector is the right choice. It offers 17 operating positions and supplies industrial, agricultural or commercial processes with a defined, stable voltage range, protected against outside influences.

Renewables

Renewables

At higher power levels but with less space, such as in wind power systems, ECOTAP® VPD® with 100 amperes and 9 operating positions is the right on-load tap-changer. It can be easily integrated into existing transformer design and helps optimize

Technology from the pioneer

Reinhausen has adapted its expertise from several decades of experience with on-load tap-changers to the specific requirements in distribution transformers continuously further developing the solution

- 2009

The first pilot projects start

n initial field tests, trials were still conducted with conventional tap changers in oil technology and the effectiveness of voltage regulated distribution transformers was proven in real-world operation.

- 2012

First series solution for voltage regulated distribution transformers.

GRIDCON® iTAP® was the first maintenance-free, highly-compact vacuum on-load tap-changer for distribution transformers. Reinhausen developed the system specifically for use in distribution grids. The system consists of an on-load tap-changer, motor-drive unit and voltage regulator.

- 2016

First high-speed resistor-type tap-changer for distribution transformers

Reinhausen launched ECOTAP® VPD® , the world’s first high-speed resistor-type tap-changer for distribution transformers with direct drive. It solved the problem of additional losses in the transformer.

- 2018

The second generation of the ECOTAP® VPD® is brought to market

It is even more economical than its predecessor and is suitable for a a broader range of applications.

YOUR CONTACT

Do you have any questions about ECOTAP® VPD® ?

Franco Pizzutto is here to help:

F.Pizzutto@reinhausen.com